| –≠–ª–µ–∫—Ç—Ä–æ–Ω–Ω—ã–π –∫–æ–º–ø–æ–Ω–µ–Ω—Ç: LTC3411 | –°–∫–∞—á–∞—Ç—å:  PDF PDF  ZIP ZIP |

1

LTC3445

3445fa

Buck Regulator

High Efficiency: Up to 93%

600mA Output Current (V

CC1

= 3V, V

OUT

= 1.3V)

Programmable Output Voltage: 0.85V to 1.55V

2.5V to 5.5V Input Voltage Range

1.5MHz Constant Frequency or Spread Spectrum

Option

Soft-Start

LDOs

Two LDO Regulators: 0.3V Dropout at 50mA

PowerPath Controller

Dynamically Regulates V

CC

BATT

I

2

C

Standard (100kHz) or Fast Mode (400kHz)

24-Lead (4mm

◊ 4mm) QFN Package

I

2

C Controllable

Buck Regulator with Two LDOs

in a 4mm

◊ 4mm QFN

Intel's Microprocessor Supply (PXA27X)

Portable Instruments

, LTC and LT are registered trademarks of Linear Technology Corporation.

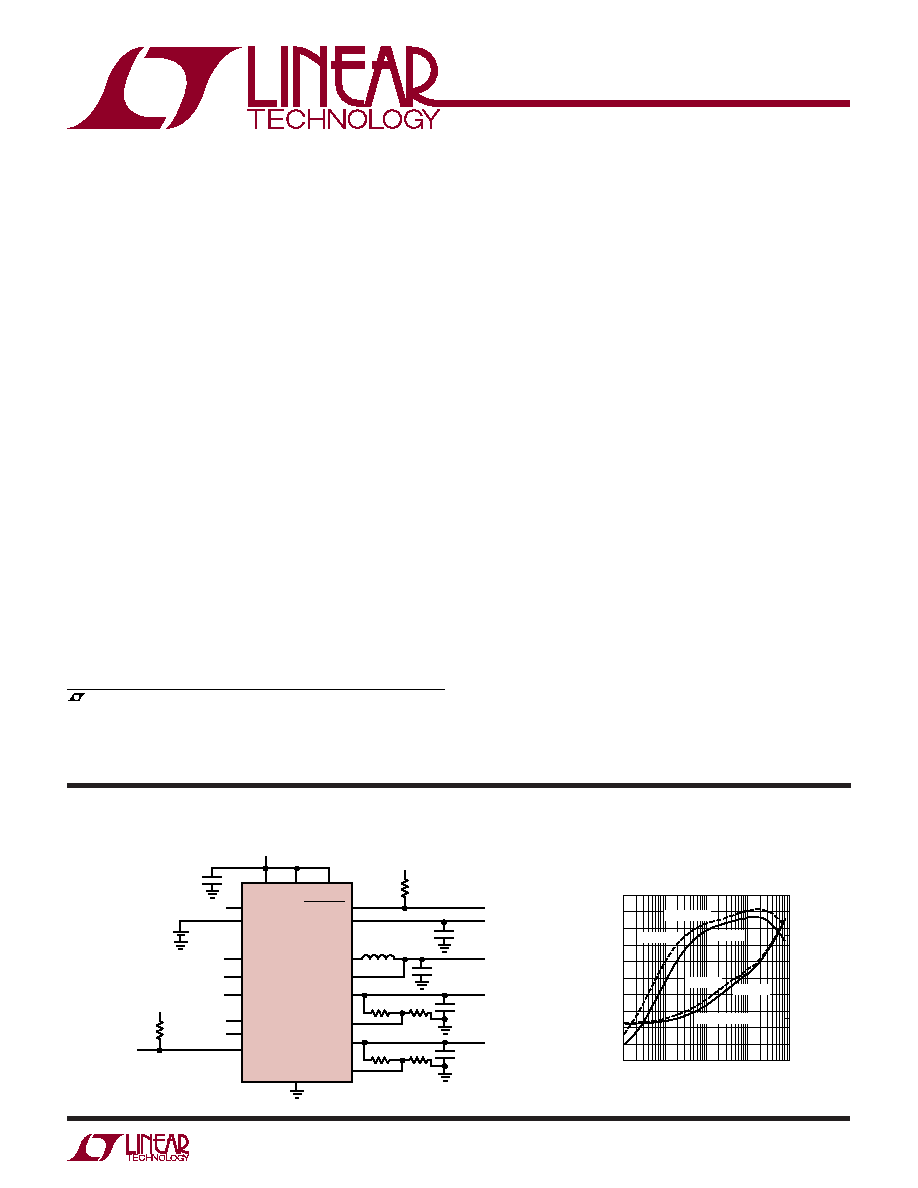

The LTC

Æ

3445 contains a high efficiency monolithic syn-

chronous current mode buck regulator, two LDO regula-

tors, a PowerPath

TM

controller and an I

2

C

TM

interface.

The buck regulator has a 6-bit programmable output range

of 0.85V to 1.55V. Also, the buck regulator uses either a

constant (1.5MHz) or a spread spectrum switching fre-

quency. Using the spread spectrum option allows for a

lower noise regulated output as well as low noise at the

input. In addition, the regulated output voltage slew rate is

programmable via the I

2

C interface.

The LTC3445 contains two LDO voltage regulators. The

regulator output voltages are externally resistor program-

mable. Each LDO is capable of delivering up to 50mA.

The LTC3445 contains control circuitry (PowerPath) for

automatic back-up battery selection. V

BACKUP

is typically

a coin cell.

Typical supply current during operation is only 360

µA and

drops to 27

µA in shutdown. The 2.5V to 5.5V input

voltage range makes the LTC3445 ideal for single Li-Ion

battery-powered applications. Automatic Burst Mode

Æ

operation increases efficiency at light loads, further ex-

tending battery life.

Burst Mode is a registered trademark of Linear Technology Corporation.

PowerPath is a trademark of Linear Technology Corporation.

I

2

C is a trademark of Philips Electronics N.V.

Protected by U.S. Patents, including 5481178, 6580258, 6304066, 6127815, 6498466,

6611131, Spread Spectrum patent pending.

FEATURES

DESCRIPTIO

U

APPLICATIO S

U

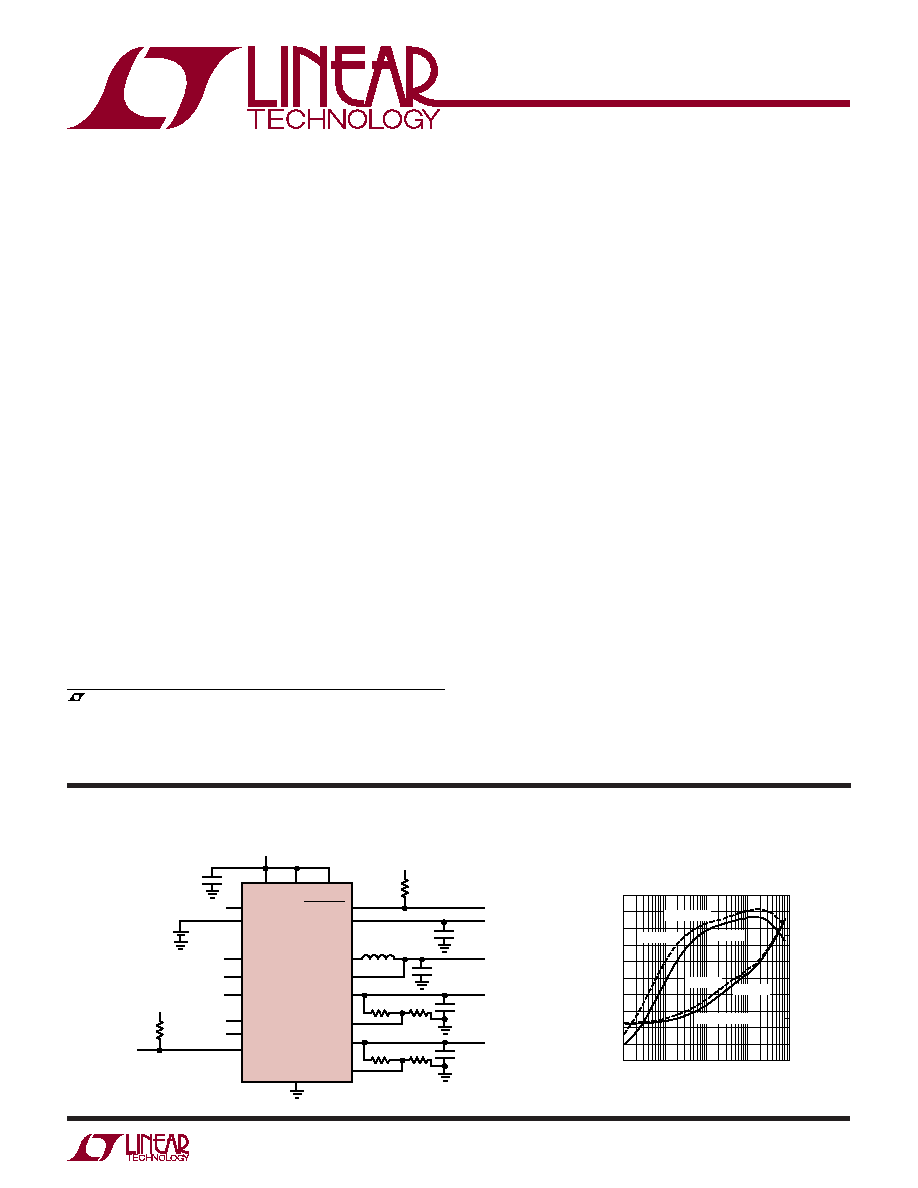

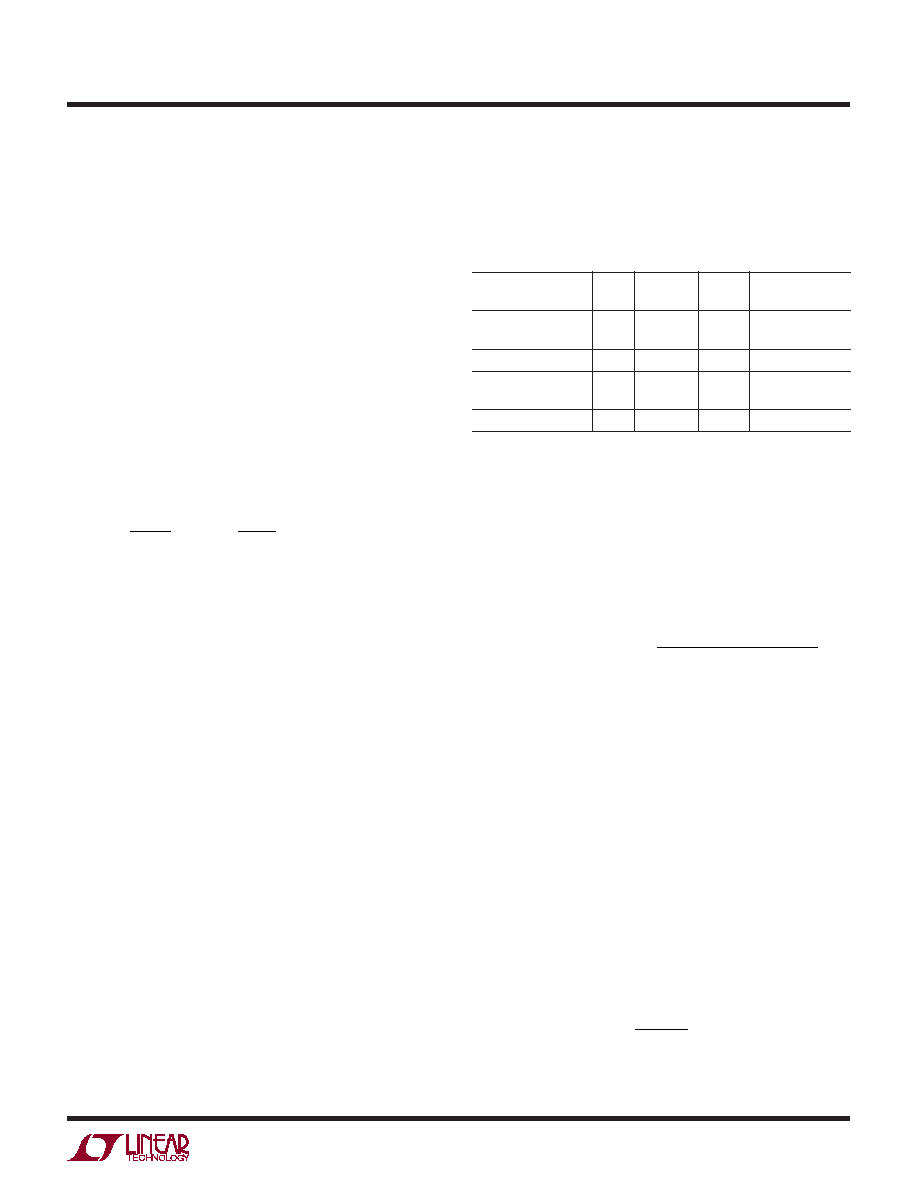

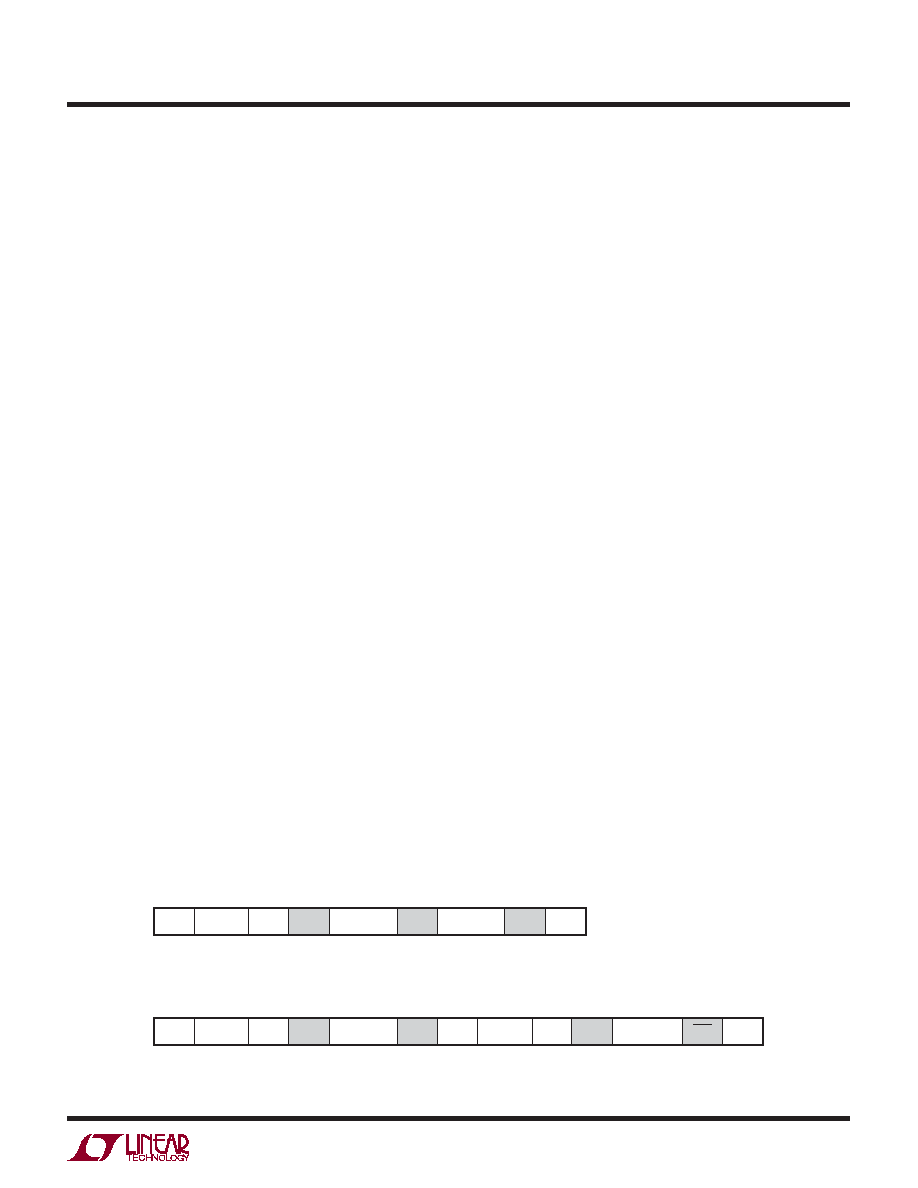

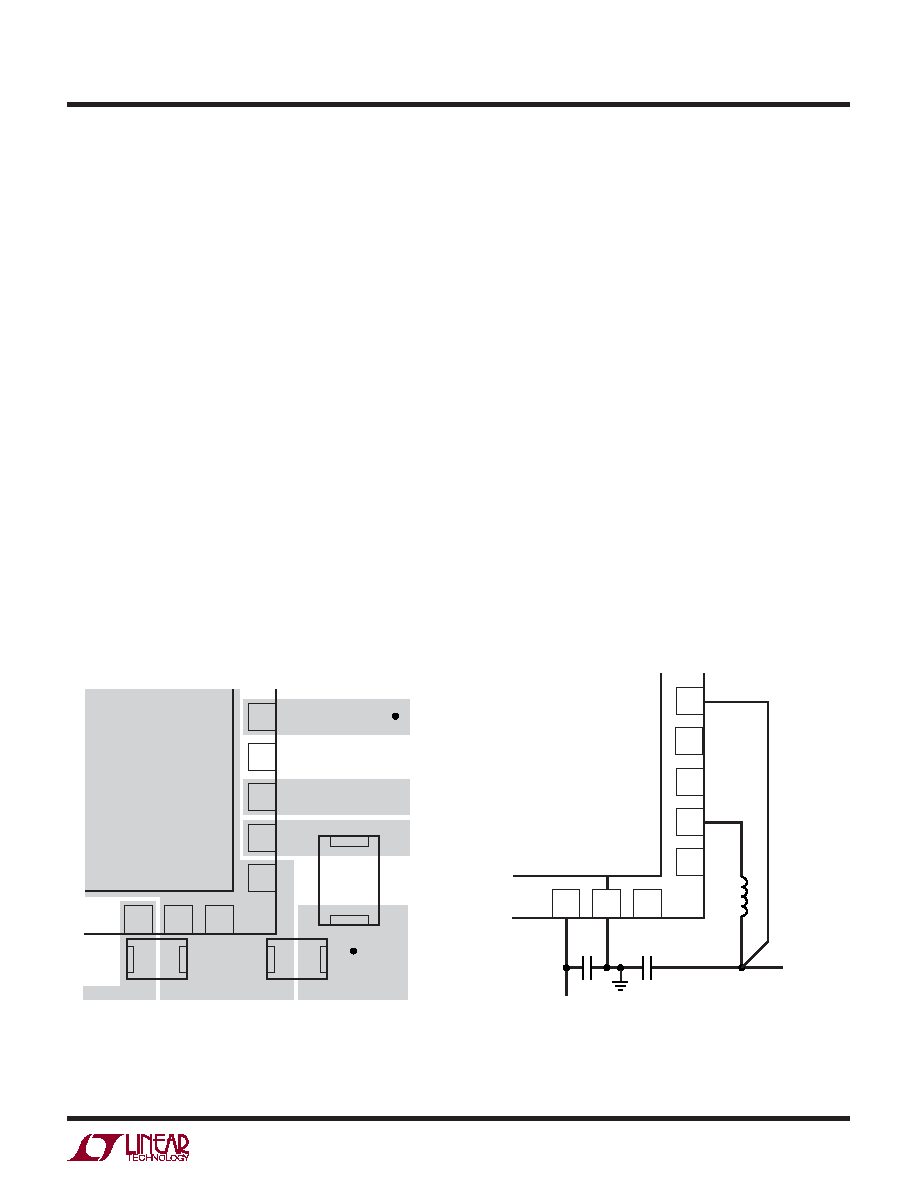

TYPICAL APPLICATIO

U

+

2.2

µH

705k

604k

4.7

µF

CER

4.7

µF

CER

10

µF

CER

1.3V

0.85V

TO 1.55V

3V

TYP

V

CC2

GND

LTC3445

V

CC1

nBATT_FAULT

V

CC1

BATTFAULT

4.7

µF

CER

V

CC

BATT

V

TRACK

3V

COIN

CELL

V

BACKUP

LDO1

LDO1FB

LDO2

LDO2FB

SW

FB

RUN

SDA

I

2

C BUS

PWR_EN

V

CC1

OR GND

V

CC1

OR GND

SCL

ADD7

ADD6

PGOOD

V

CC

nV

CC

_FAULT

V

CC

20k

3445 TA01

503k

604k

10

µF

CER

1.1V

V

BACKUP

20k

V

BACKUP

Efficiency and Power Loss

vs Load Current, V

CC1

= 3.6V

LOAD CURRENT (mA)

30

EFFICIENCY (%)

POWER LOSS (mW)

90

100

20

10

80

50

70

60

40

0.1

10

100

1000

3445 TA01b

0

1

DAC MAX

DAC MIN

DAC MIN

DAC MAX

100

1000

10

1.0

0.1

EFFICIENCY

POWER LOSS

2

LTC3445

3445fa

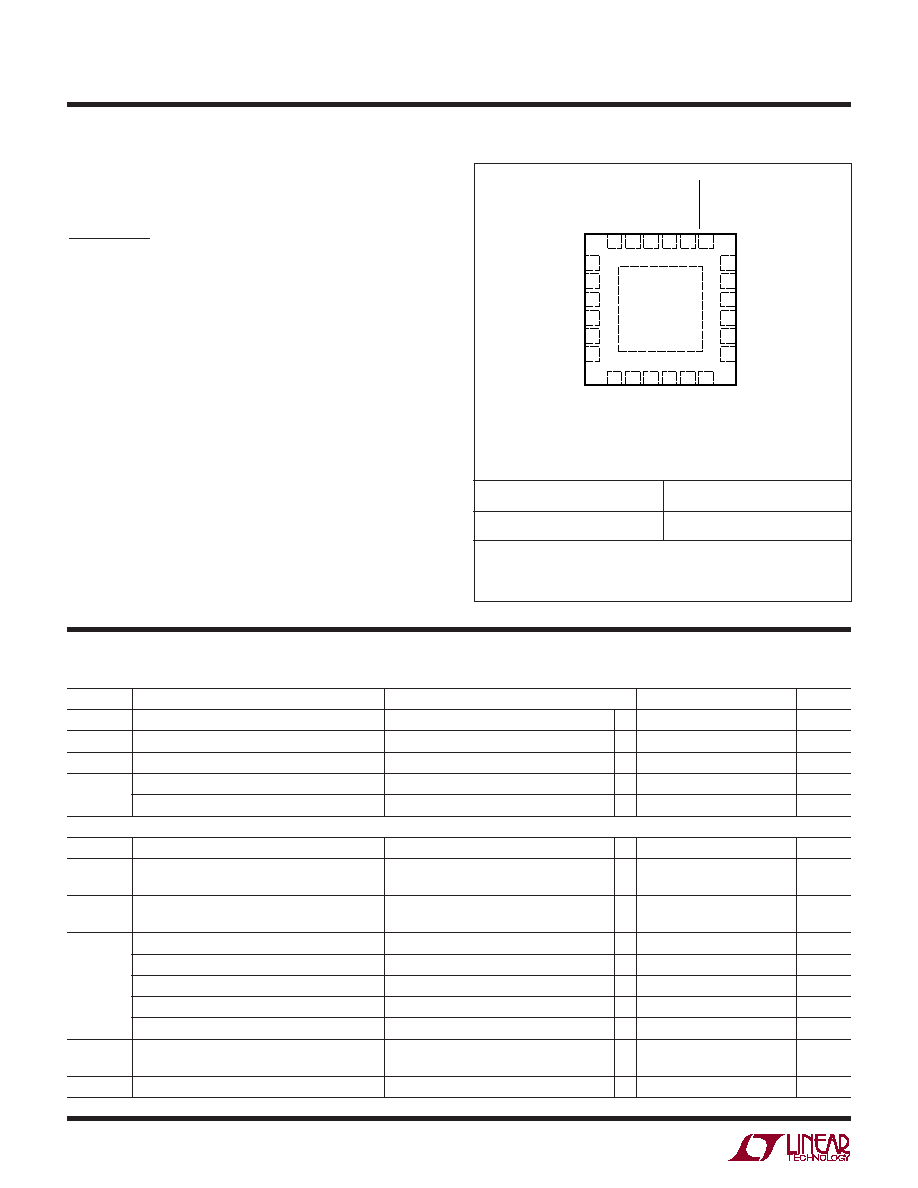

Order Options Tape and Reel: Add #TR

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking:

http://www.linear.com/leadfree/

ORDER PART NUMBER

(Note 1)

ABSOLUTE AXI U RATI GS

W

W

W

U

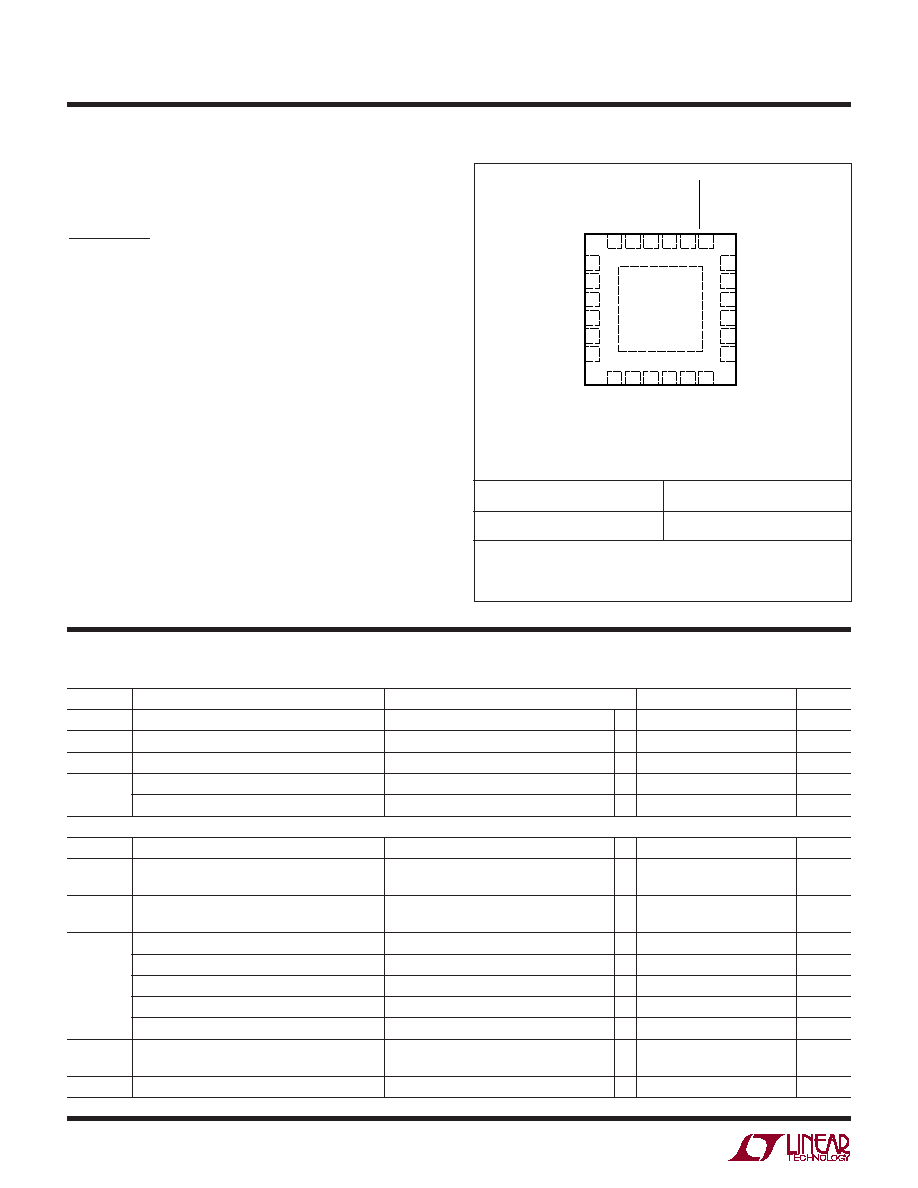

PACKAGE/ORDER I FOR ATIO

U

U

W

Consult LTC Marketing for parts specified with wider operating temperature ranges.

LTC3445EUF

T

JMAX

= 125

∞C,

JA

= 37

∞C/W,

JC

= 2.6

∞C/W

EXPOSED PAD (PIN 25) IS GND, MUST BE SOLDERED TO PCB

24 23 22 21 20 19

7

8

9

TOP VIEW

25

UF PACKAGE

24-LEAD (4mm

◊ 4mm) PLASTIC QFN

10 11 12

6

5

4

3

2

1

13

14

15

16

17

18

V

TRACK

V

BACKUP

V

CC1

PGOOD

ADD7

SDA

V

CC

BATT

FB

NC

RUN

SW

NC

LDO2FB

LDO2

V

CC2

LDO1

LDO1FB

BATTFAULT

NC

SCL

ADD6

V

CC1

GND

NC

The

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

∞C. V

CC1

= V

CC2

= 3.6V, unless otherwise noted.

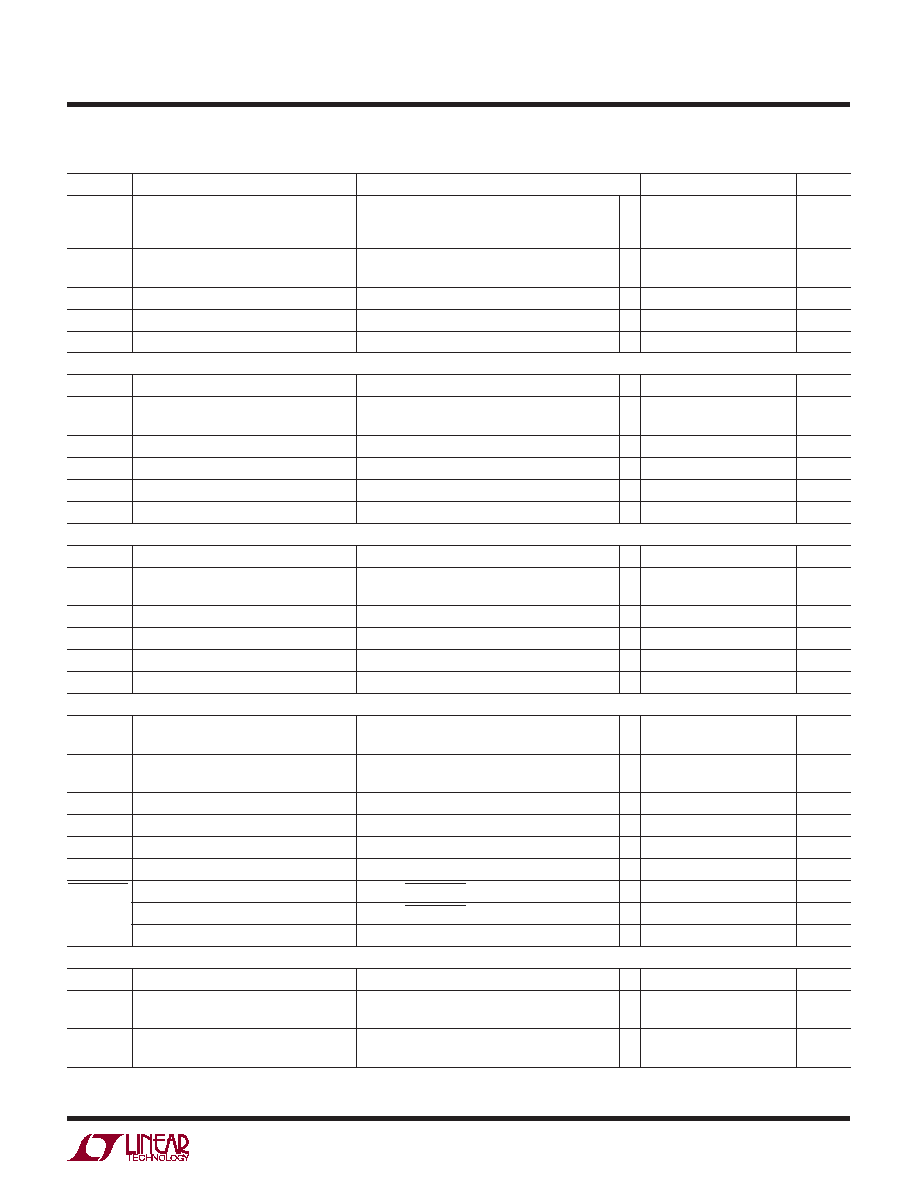

ELECTRICAL CHARACTERISTICS

UF PART MARKING

3445

V

CC1

, V

CC2

, SDA, SCL Voltages .................. ≠ 0.3V to 6V

RUN, V

TRACK

, V

BACKUP

, PGOOD, ADD7,

ADD6, FB, V

CC

BATT,

BATTFAULT Voltages .............................. ≠ 0.3V to V

CC1

SW Voltage ................................ ≠ 0.3V to (V

CC1

+ 0.3V)

LDO1FB, LDO2FB Voltages ..................... ≠ 0.3V to V

CC2

LDO1, LDO2 Voltages ................ ≠ 0.3V to (V

CC2

+ 0.3V)

LDO1, LDO2 Source Current ............................... 50mA

V

CC

BATT Source Current ...................................... 8mA

P-Channel Switch Source Current (DC) ............. 800mA

N-Channel Switch Sink Current (DC) ................. 800mA

Peak SW Sink and Source Current ........................ 1.3A

LDO1, LDO2, V

CC

BATT Output Short-Circuit

Duration .......................................................... Indefinite

Operating Temperature Range (Note 2) ...≠40

∞C to 85∞C

Junction Temperature (Note 3) ............................ 125

∞C

Storage Temperature Range ................. ≠65

∞C to 125∞C

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

V

CC1,

V

CC2

Input Voltage Range

2.5

5.5

V

RUN

Run Threshold

0.3

1

1.5

V

PGOOD

Reports Undervoltage of any Regulator

PGOOD = 0.4V

3

mA

I

S

DC Bias Current (Shutdown)

RUN = 0

27

50

µA

DC Bias Current (Buck, LDO1, LDO2 Disabled)

RUN = V

CC1

105

150

µA

Buck Regulator

R

FB

Feedback Resistance

340

k

V

OUT(MIN)

Regulated Output Voltage

I

OUT

= 100mA, Burst Mode Operation

0.824

0.850

0.875

V

Disabled

V

OUT(MAX)

Regulated Output Voltage

I

OUT

= 100mA, Burst Mode Operation

1.504

1.55

1.597

V

Disabled

V

OUT(STEP)

Output Voltage Step Size (0 to 48)

I

OUT

= 100mA

13.1

14.7

16.1

mV

Output Voltage Slew Rate = 00

I

OUT

= 100mA, V

OUT

= 0.85V to 1.55V

11.3

mV/

µs

Output Voltage Slew Rate = 01

I

OUT

= 100mA, V

OUT

= 0.85V to 1.55V

7.5

mV/

µs

Output Voltage Slew Rate = 10

I

OUT

= 100mA, V

OUT

= 0.85V to 1.55V

3.8

mV/

µs

Output Voltage Slew Rate = 11

I

OUT

= 100mA, V

OUT

= 0.85V to 1.55V

0.9

mV/

µs

I

PK

Peak Inductor Current

V

CC1

= 3V, V

FB

= 0.5V or V

OUT

= 90%,

0.75

1

1.25

A

Duty Cycle < 35%

V

LOADREG

Output Voltage Load Regulation

0.5

%

3

LTC3445

3445fa

The

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

∞C. V

CC1

= V

CC2

= 3.6V, unless otherwise noted.

ELECTRICAL CHARACTERISTICS

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

I

S

Additional Input DC Bias Current For Buck (Note 4)

Active Mode

V

OUT

= 90%, I

LOAD

= 0A

220

µA

Sleep Mode

V

OUT

= 103%, I

LOAD

= 0A

6

µA

f

OSC

Nominal Oscillator Frequency

V

OUT

= 100%

1.2

1.5

1.8

MHz

V

OUT

= 0V

300

kHz

R

PFET

R

DS(ON)

of P-Channel FET

I

SW

= 100mA

0.45

R

NFET

R

DS(ON)

of N-Channel FET

I

SW

= ≠100mA

0.325

I

LSW

SW Leakage

V

RUN

= 0V, V

SW

= 0V or 5V, V

CC1

= 5V

1

µA

LDO1

I

S

Additional DC Bias for LDO1

23

30

µA

V

OUT

Regulated Output Voltage

2.5V < V

IN

< 5.5V, 1mA < I

LOAD

< 50mA

0.582

V

CC2

≠

V

0.3

Line Regulation

V

CC2

= 2.5V to 5.5V, I

LOAD

= 1mA, V

OUT

= 1.2V

1

5

mV

Load Regulation

V

CC2

= 2.5V,

I

LOAD

= 1mA to 50mA, V

OUT

= 1.2V

15

mV

Dropout Voltage

I

LOAD

= 50mA

0.3

V

V

FB

LDO Feedback Voltage

I

LOAD

= 0mA

0.582

0.6

0.618

V

LDO2

I

S

Additional DC Bias for LDO2

23

30

µA

V

OUT

Regulated Output Voltage

2.5V < V

IN

< 5.5V, 1mA < I

LOAD

< 50mA

0.582

V

CC2

≠

V

0.3

Line Regulation

V

CC2

= 2.5V to 5.5V, I

LOAD

= 1mA, V

OUT

= 1.2V

1

5

mV

Load Regulation

V

CC2

= 2.5V,

I

LOAD

= 1mA to 50mA, V

OUT

= 1.2V

15

mV

Dropout Voltage

I

LOAD

= 50mA

0.3

V

V

FB

LDO Feedback Voltage

I

LOAD

= 0mA

0.582

0.6

0.618

V

PowerPath Controller

V

TRACK

Tracked Input Voltage

3

V

CC1

≠

V

0.2

V

TRACK

≠

Tracked Output Voltage at V

CC

BATT

3V < V

TRACK

< V

CC1

≠ 0.2V

≠0.2

0

0.2

V

V

CC

BATT

V

BACKUP

Backup Battery Voltage

2

5.5

V

I

BACKUP

Backup Battery Bias Current

V

CC1

= V

TRACK

= 0V, V

BACKUP

= 2.5V

4

6.5

µA

V

CC

BATT

V

CC

BATT Output

V

TRACK

= 0V, V

CC1

= 4V, I

VCCBAT

= 8mA

2.85

3

3.1

V

I

VCCBATT

Max V

CC

BATT Output Current

V

CC1

= 2.5V

8

mA

BATTFAULT V

CC1

High Level (Good)

Where BATTFAULT Goes High

2.65

2.8

2.9

V

V

CC1

Low Level (Bad)

Where BATTFAULT Goes Low

2.4

2.5

2.6

V

Hysteresis

V

CC1

= 0V to 4.2V, 4.2 to 0V

0.3

V

I

2

C Interface

f

I2C(MAX)

Maximum I

2

C Operating Frequency

(Note 5)

400

kHz

t

BUF

Bus Free Time Between Stop and Start

(Note 5)

1.3

µs

Condition

t

HD(RSTA)

Hold Time After (Repeated)

(Note 5)

600

ns

Start Condition

4

LTC3445

3445fa

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3445EUF is guaranteed to meet performance specifica-

tions from 0

∞C to 70∞C. Specifications over the ≠40∞C to 85∞C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

ELECTRICAL CHARACTERISTICS

Note 3: T

J

is calculated from the ambient temperature, T

A

, and power

dissipation, P

D

, according to the following formula:

T

J

= T

A

+ P

D

∑ 37

∞C/W

Note 4: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency.

Note 5: Determined by design, not production tested.

The

denotes the specifications which apply over the full operating

temperature range, otherwise specifications are at T

A

= 25

∞C. V

CC1

= V

CC2

= 3.6V, unless otherwise noted.

ELECTRICAL CHARACTERISTICS

SYMBOL

PARAMETER

CONDITIONS

MIN

TYP

MAX

UNITS

t

SU(RSTA)

Repeated Start Condition Setup Time

(Note 5)

600

ns

t

SU(STOP)

Stop Condition Setup Time

(Note 5)

600

ns

t

HD(DIN)

Data Hold Time, Input

(Note 5)

0

ns

t

SU(DAT)

Data Setup Time

(Note 5)

100

ns

V

THR

SCL and SDA Logic Input Threshold

1.8

V

V

HYS

SCL and SDA Logic Input Hysteresis

(Note 5)

50

mV

I

LVTRACK

V

TRACK

Leakage

V

CC

= 3.6V

1.44

2.2

µA

I

LVBACKUP

V

BACKUP

Leakage

V

CC

= 3.6V

1

µA

I

LADD7

ADD7 Leakage

V

CC

= 3.6V

1

µA

I

LADD6

ADD6 Leakage

V

CC

= 3.6V

1

µA

I

LSCL

SCL Leakage

V

CC

= 3.6V

1

µA

I

LSDA

SCL Leakage

V

CC

= 3.6V

1

µA

I

LLDO1

LDO1 Leakage

V

CC

= 3.6V, RUN = 0

1

µA

I

LLDO2

LDO2 Leakage

V

CC

= 3.6V, RUN = 0

1

µA

I

LLDO1FB

LDO1FB Leakage

V

CC

= 3.6V, RUN = 0

1

µA

I

LLDO2FB

LDO2FB Leakage

V

CC

= 3.6V, RUN = 0

1

µA

I

LBATTFAULT

BATTFAULT Leakage

V

CC

= 3.6V

1

µA

I

FB1,2

LDO Feedback Input Current

V

FB1

= 0.6V

1

µA

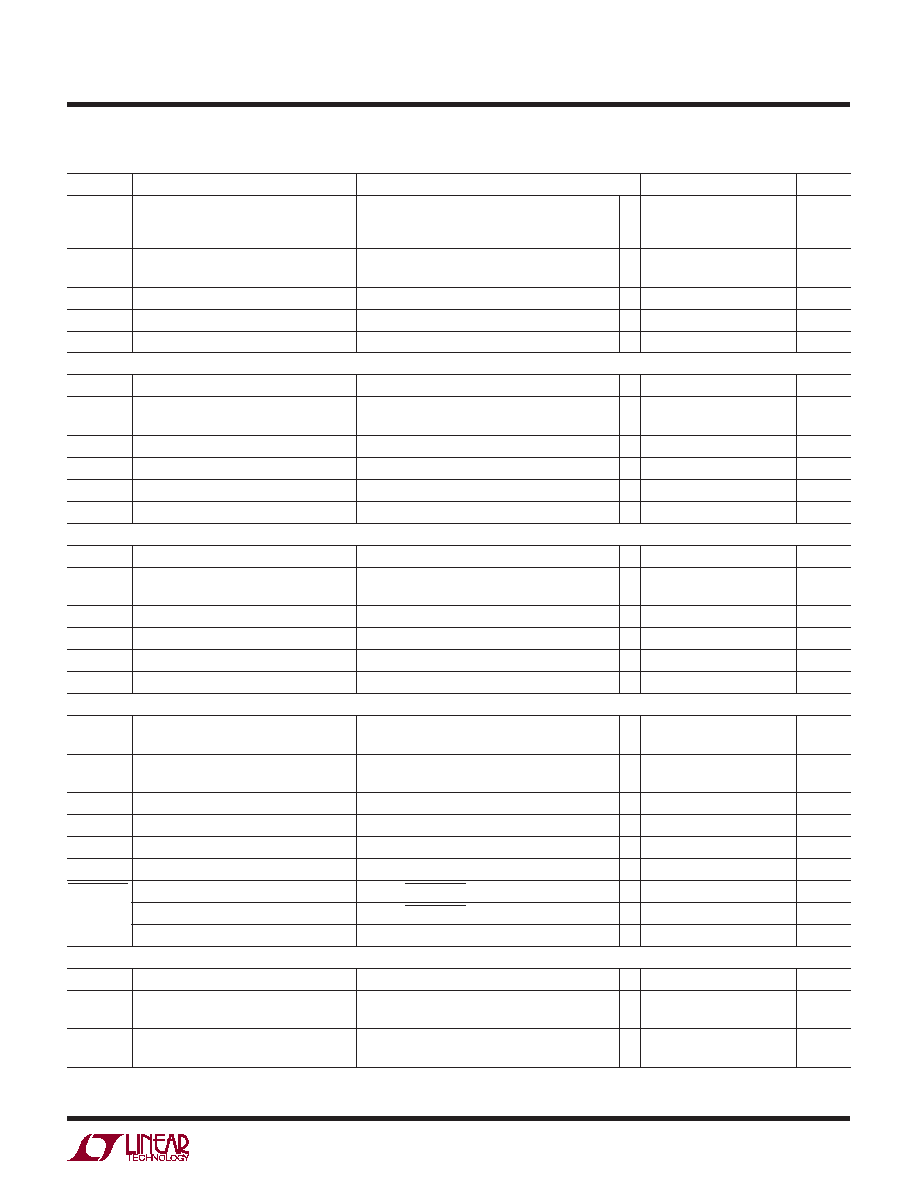

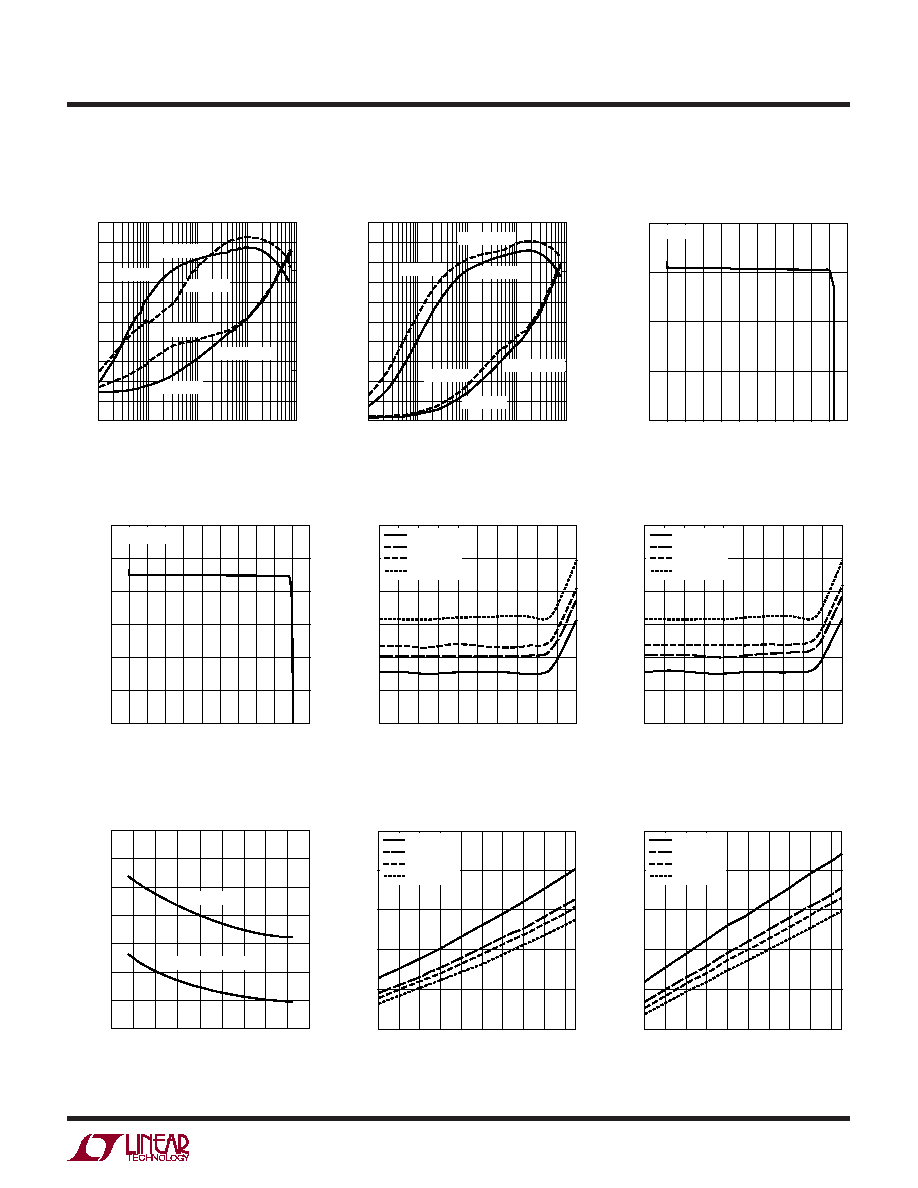

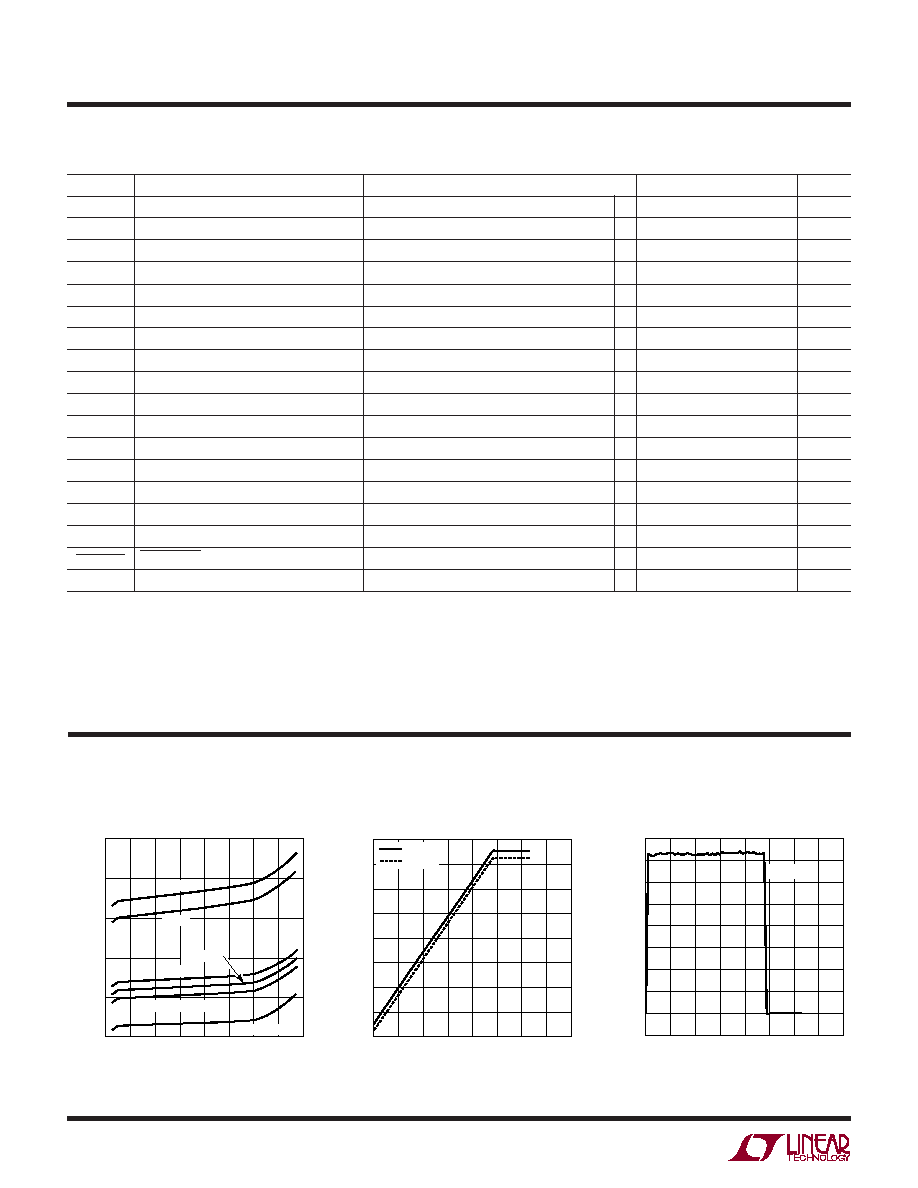

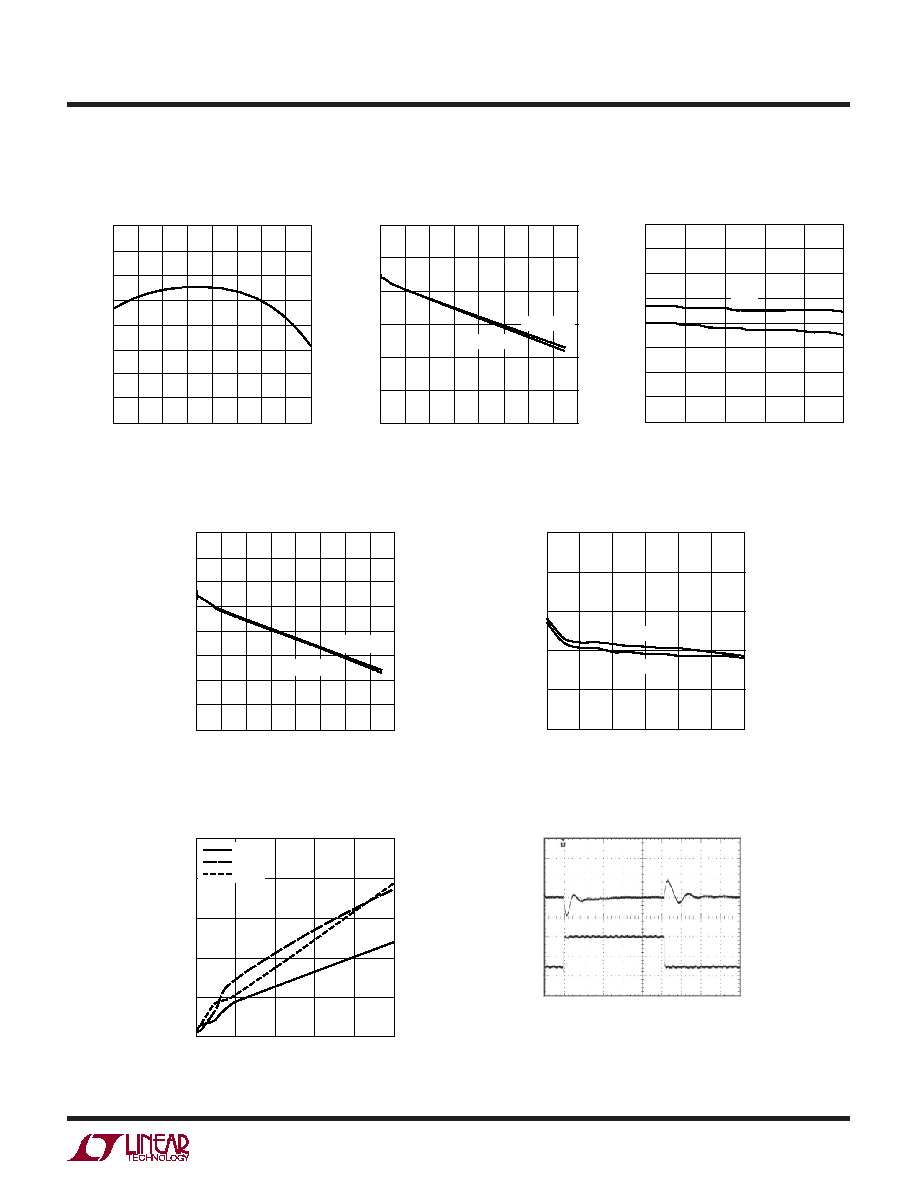

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Supply Current vs Supply Voltage

SUPPLY VOLTAGE (V)

2.4

SUPPLY CURRENT (

µ

A)

300

400

500

3.6

4.4

5.6

3445 G01

200

100

0

2.8

3.2

4

4.8

5.2

ALL ON

BUCK

TWO LDOs

RUN = HIGH

RUN = LOW

ONE LDO

V

OUT

vs DAC

DAC VALUE

0

V

OUT

(V)

1.2

1.4

80

3445 G02

1.0

0.8

20

40

60

10

30

50

70

1.6

1.1

1.3

0.9

1.5

0mA

600mA

DAC VALUE

0

V

OUT(N)

≠ V

OUT(N≠1)

(V)

0.008

0.010

0.012

80

3445 G03

0.006

0.004

≠0.002

20

40

60

10

30

50

70

0.002

0

0.016

0.014

100mA

V

OUT

Step Size vs DAC

5

LTC3445

3445fa

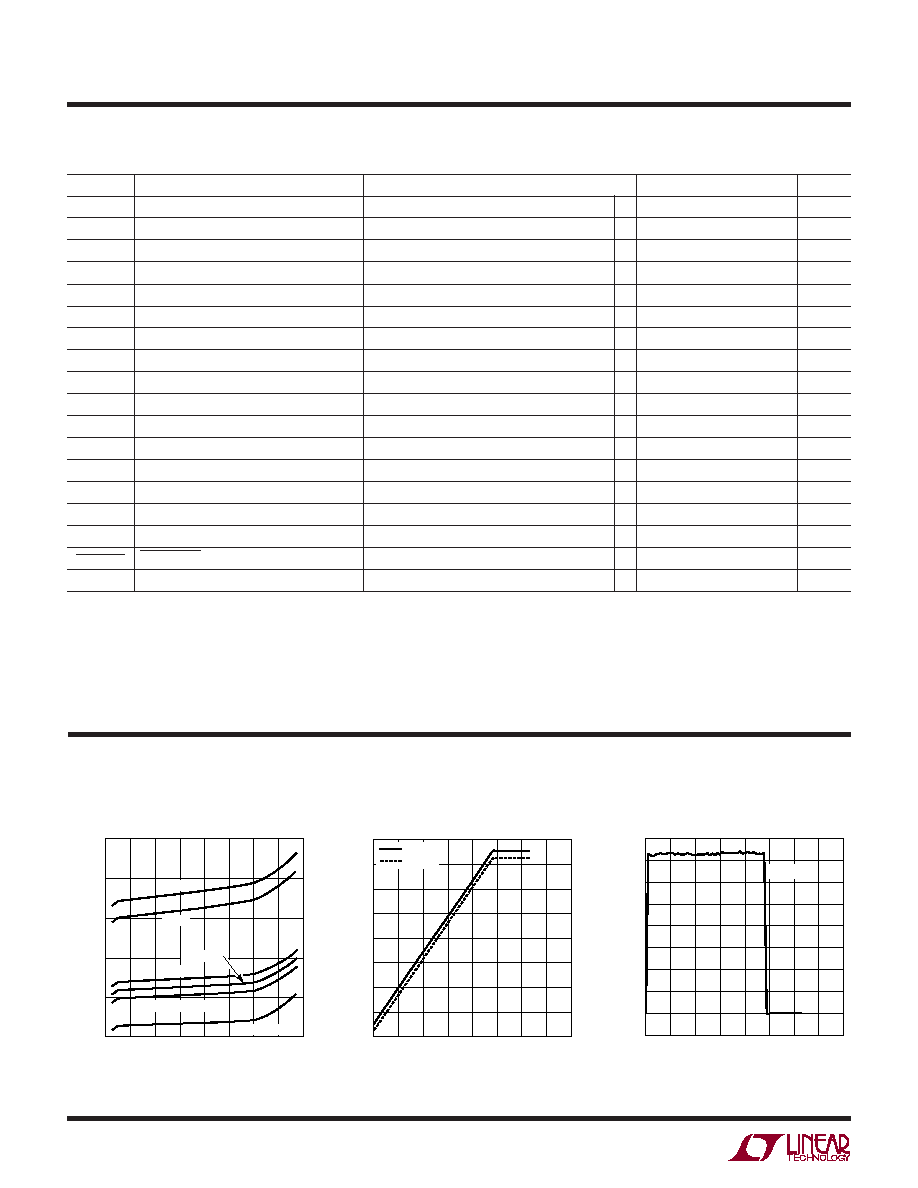

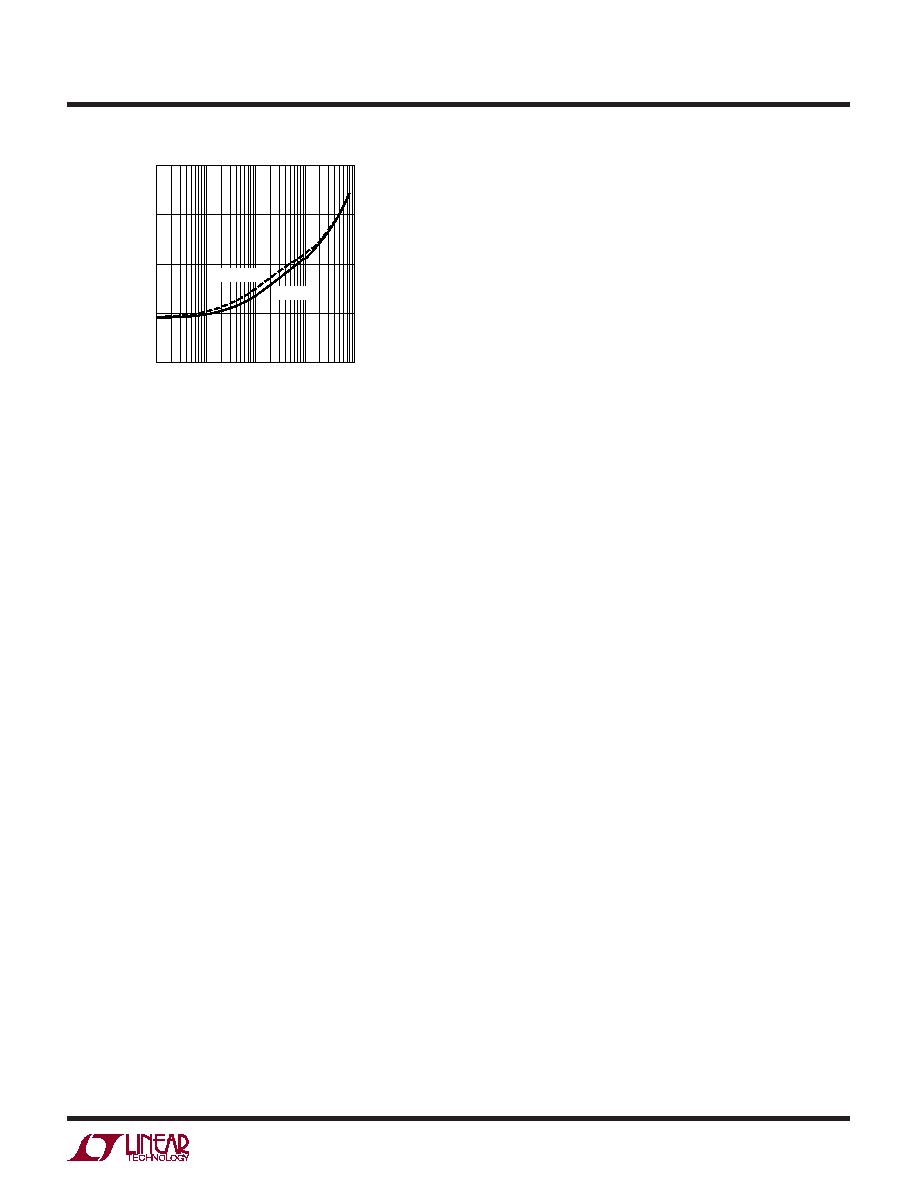

Buck Efficiency and Power Loss

vs Load Current, V

CC1

= 2.5V

Buck Output Voltage

vs Load Current

LOAD CURRENT (mA)

30

EFFICIENCY (%)

POWER LOSS (mW)

90

100

20

10

80

50

70

60

40

0.1

10

100

1000

3445 G04

0

1

100

1000

10

1.0

0.1

DAC MAX

DAC MIN

DAC MIN

DAC MAX

EFFICIENCY

POWER LOSS

LOAD CURRENT (mA)

30

EFFICIENCY (%)

POWER LOSS (mW)

90

100

20

10

80

50

70

60

40

0.1

10

100

1000

3445 G05

0

1

100

1000

10

1.0

0.1

DAC MAX

DAC MIN

DAC MIN

DAC MAX

EFFICIENCY

POWER LOSS

LOAD CURRENT (mA)

≠100

BUCK OUTPUT (V)

0.800

0.850

700

3445 G06

0.750

0.700

100

300

0.900

500

900

DAC = MIN

Buck Output Voltage

vs Load Current

I

VCC2

vs Temperature (RUN = V

CC1

)

LOAD CURRENT (mA)

≠100

BUCK OUTPUT (V) 1.500

1.540

1.520

1.560

700

3445 G07

1.480

1.460

100

300

1.580

500

900

DAC = MAX

TEMPERATURE (

∞C)

0

V

CC2

LEAKAGE CURRENT (

µ

A)

0.4

0.8

1.2

0.2

0.6

1.0

≠10

30

70

110

3445 G08

150

≠50

V

CC2

= 2.5V

V

CC2

= 3.6V

V

CC2

= 4.2V

V

CC2

= 5.5V

I

VCC2

vs Temperature (RUN = 0V)

TEMPERATURE (

∞C)

0

V

CC2

LEAKAGE CURRENT (

µ

A)

0.4

0.8

1.2

0.2

0.6

1.0

≠10

30

70

110

3445 G09

150

≠50

V

CC2

= 2.5V

V

CC2

= 3.6V

V

CC2

= 4.2V

V

CC2

= 5.5V

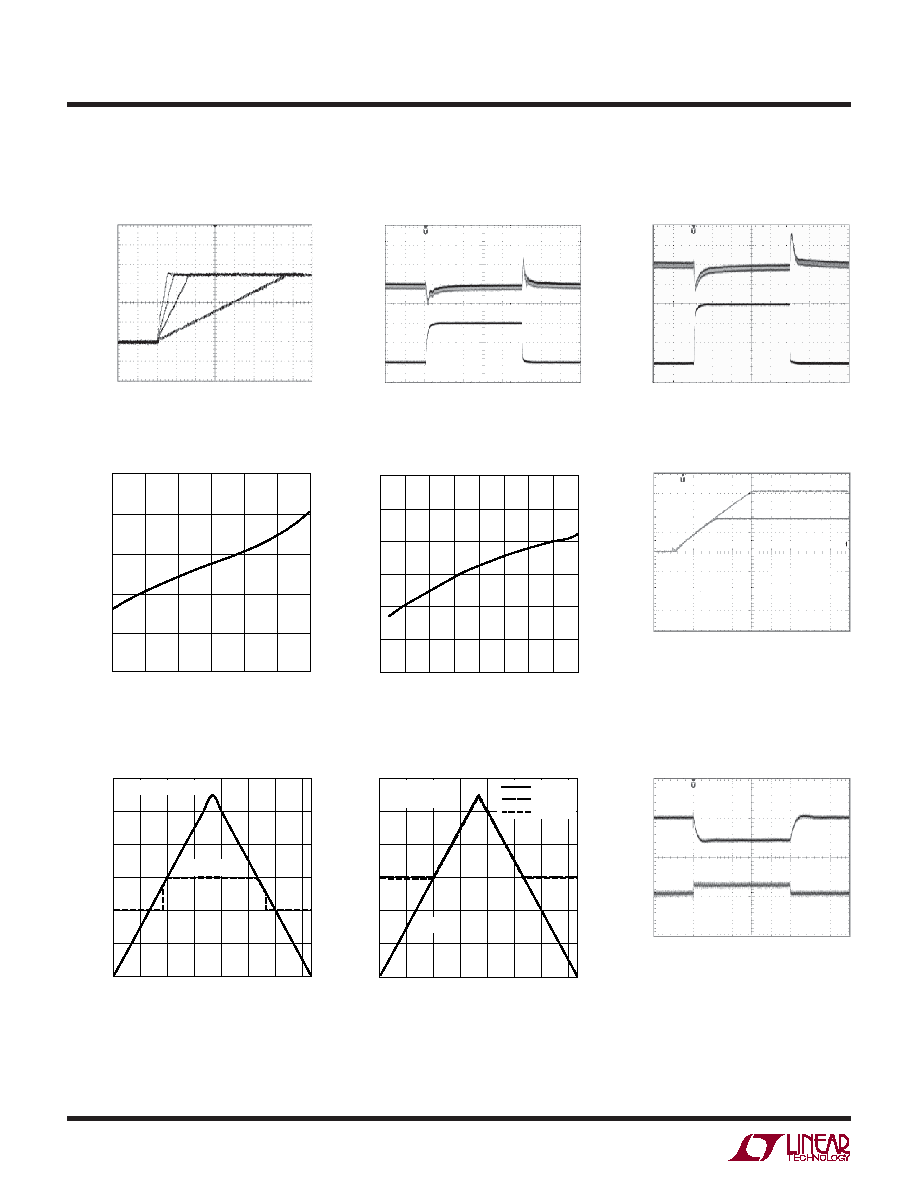

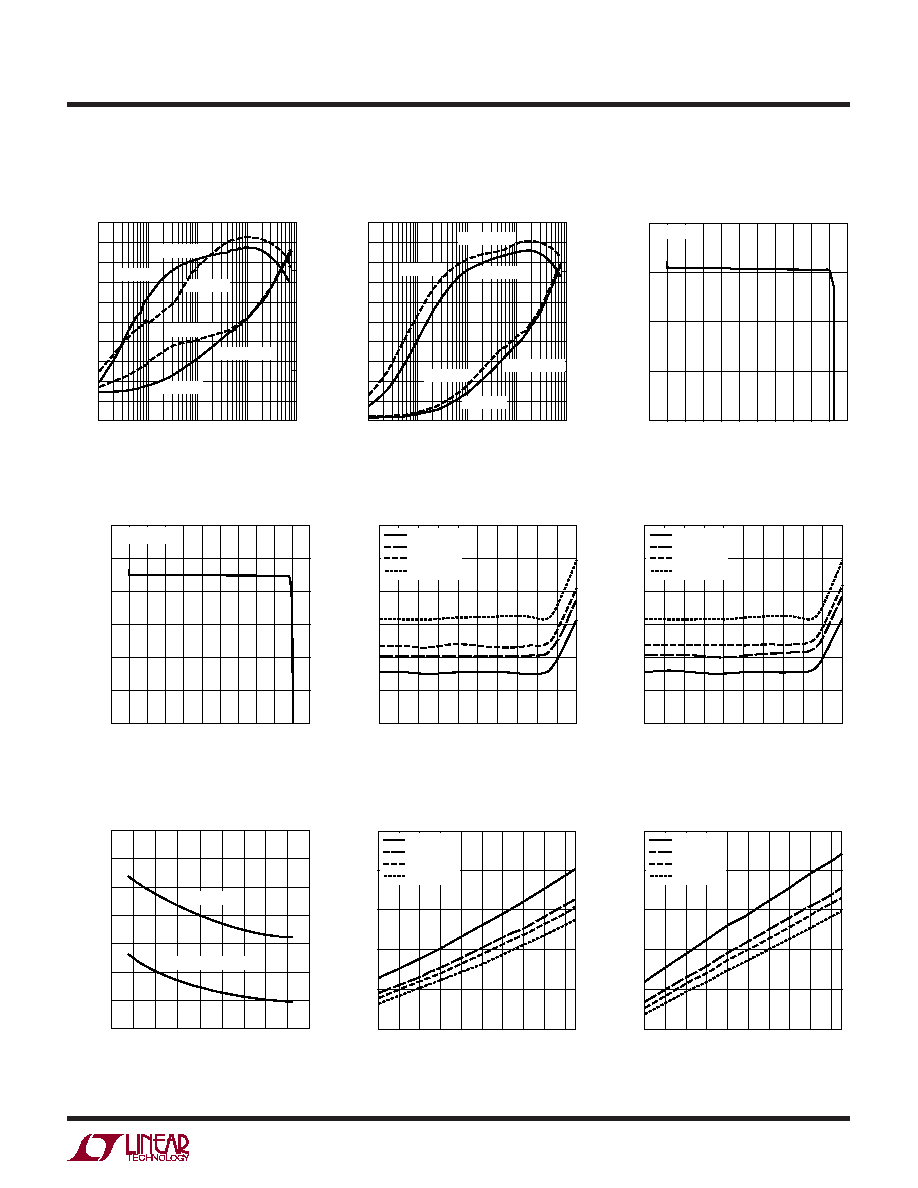

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

R

DS(ON)

vs Input Voltage

Synchronous Switch R

DS(ON)

vs Temperature

INPUT VOLTAGE (V)

2.2 2.6

3

3.4 3.8 4.2 4.6

5

5.4

250

R

DS(ON)

(m

)

300

400

450

500

600

3445 G10

350

5.8

550

MAIN SWITCH

SYNCHRONOUS SWITCH

TEMPERATURE (

∞C)

≠40

R

DS(ON)

(m

)

500

600

700

120

3445 G11

400

300

200

≠20

0

20

40

60

80 100

140

V

CC1

= 2.5V

V

CC1

= 3.6V

V

CC1

= 4.2V

V

CC1

= 5.5V

Main Switch R

DS(ON)

vs Temperature

TEMPERATURE (

∞C)

≠40

R

DS(ON)

(m

)

600

700

800

120

3445 G12

500

400

300

≠20

0

20

40

60

80 100

140

V

CC1

= 2.5V

V

CC1

= 3.6V

V

CC1

= 4.2V

V

CC1

= 5.5V

Buck Efficiency and Power Loss

vs Load Current, V

CC1

= 4.2V

6

LTC3445

3445fa

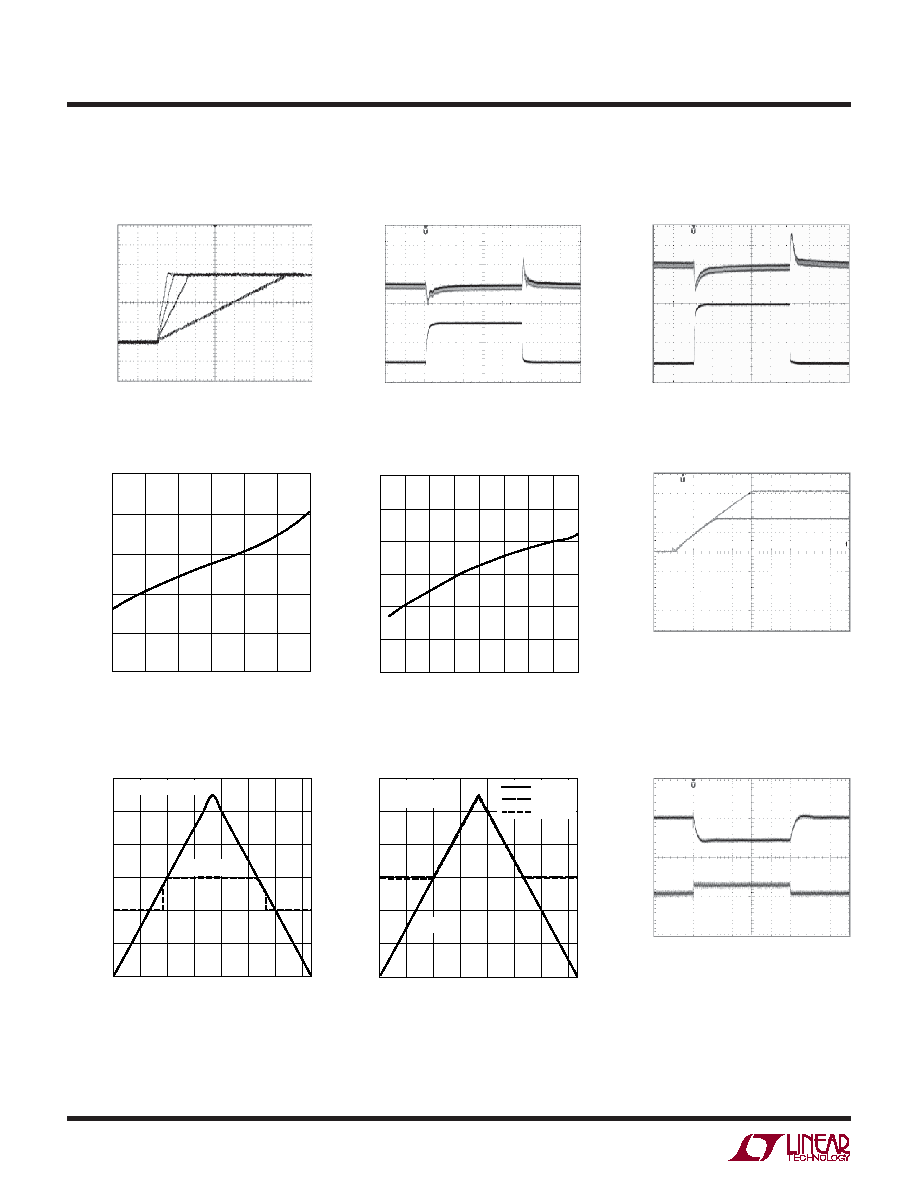

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

Slew Rates DAC Min to DAC Max

Buck (DAC = Min)

100mA to 300mA Load Step

Buck Switching Frequency

vs V

CC1

Buck (DAC = Max)

100mA to 400mA Load Step

BUCK

VOLTAGE

50mV/DIV

LOAD

CURRENT

100mA/DIV

100

µs/DIV

3445 G13

20

µs/DIV

3445 G14

20

µs/DIV

3445 G15

Buck Switching Frequency

vs Temperature

Soft-Start (DAC = Min and Max)

4.7

Load

BUCK

OUTPUTS

500mV/DIV

200

µs/DIV

3445 G18

200mV/DIV

BUCK

VOLTAGE

50mV/DIV

LOAD

CURRENT

100mA/DIV

2.5

1.40

SWITCHING FREQUENCY (MHz) 1.44

1.48

1.52

1.56

1.60

3.5

4.5

3445 G16

5.5

V

CC1

(V)

TEMPERATURE (

∞C)

≠50

1.460

1.440

SWITCHING FREQUENCY (MHz)

1.480

1.500

0

50

100

150

3445 G17

1.520

1.540

1.560

≠25

25

75

125

V

CC

BATT vs V

CC1

PowerPath LDO Load Step

1mA to 5.5mA

V

CC1

RAMP (V)

0

0

VOLTAGE (V)

1

2

3

V

CC1

4

3445 G19

5

6

V

TRACK

= V

BACKUP

= 2V

V

CC

BATT

V

CC

BATT vs V

TRACK

V

TRACK

RAMP (V)

0

0

VOLTAGE (V)

1

2

3

4

3445 G20

5

6

V

CC1

= 5.5V

V

BACKUP

= 2V

V

CC

BATT

0mA

5mA

V

TRACK

V

CC

BATT

20mV/DIV

LOAD

CURRENT

10mA/DIV

200

µs/DIV

3445 G21

7

LTC3445

3445fa

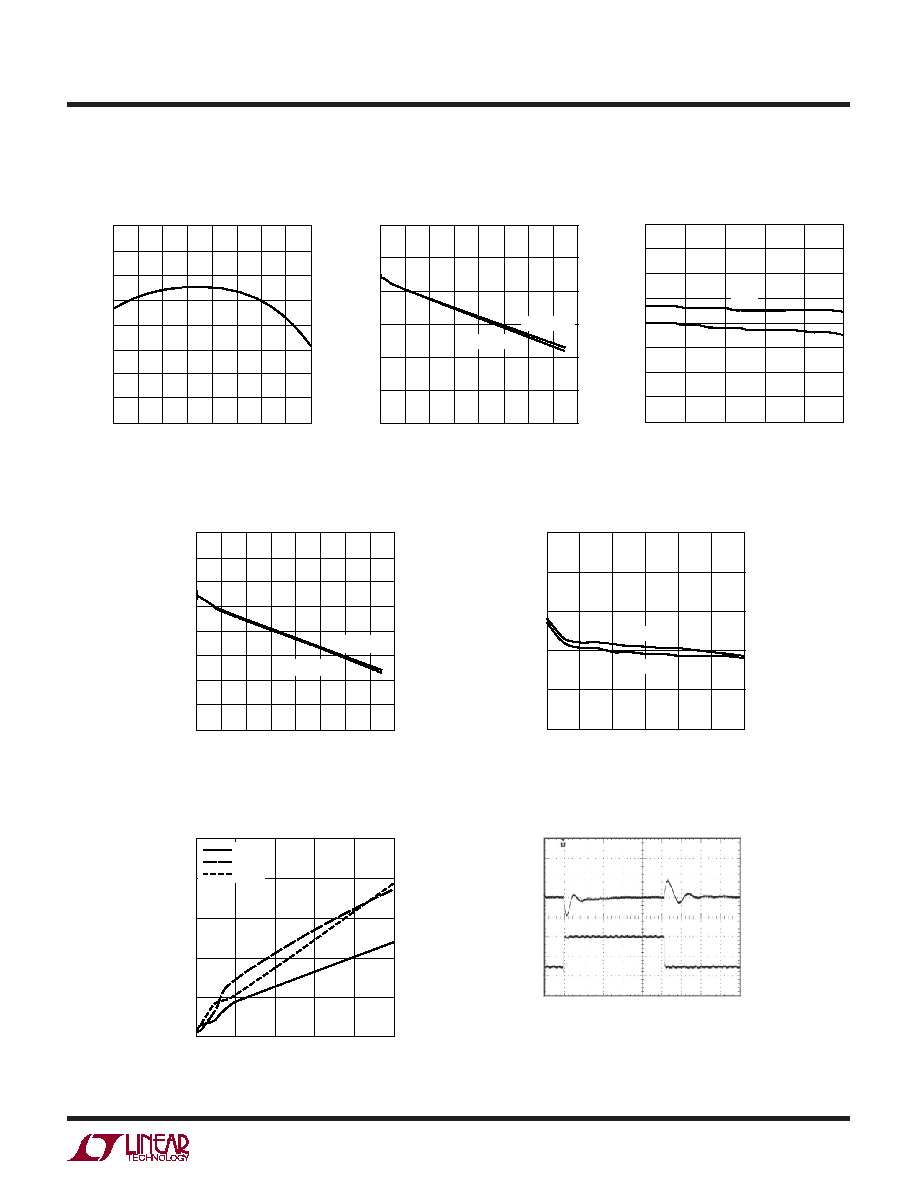

TYPICAL PERFOR A CE CHARACTERISTICS

U

W

LDO Reference Voltage

vs Temperature

LDO Reference Voltage

vs Load Current

TEMPERATURE (

∞C)

≠50

LDO REFERENCE VOLTAGE (V)

0.598

25

3445 G22

0.596

≠25

0

150

50

0mA

75

100 125

0.594

0.592

0.590

0.498

0.600

0.602

0.604

LOAD CURRENT (mA)

0

LDO REFERENCE VOLTAGE (V)

0.604

0.606

0.608

30

50

80

3445 G23

0.602

0.600

0.598

0.596

10

20

40

60

70

V

CC2

= 2.5V

V

CC2

= 5.5V

LDO Output Voltage vs V

CC2

V

CC2

(V)

2.5

LDO OUTPUT VOLTAGE (V)

1.197

1.198

1.199

4.3

5.5

3445 G24

1.196

1.195

1.194

3.1

3.7

4.9

1.200

1.201

1.202

10mA

50mA

LDO Output Voltage

vs Load Current

LDO Output Voltage

vs Load Current

LOAD CURRENT (mA)

0

2.578

2.576

2.574

LDO OUTPUT VOLTAGE (V)

2.580

2.582

2.584

2.586

2.588

2.590

10

20

30

40

3445 G25

50

60

70

80

V

CC2

= 3.6V

V

CC2

= 5.5V

LOAD CURRENT (mA)

0

LDO OUTPUT VOLTAGE (V)

1.194

1.196

1.198

1.200

1.202

1.204

10

20

30

40

3445 G26

50

60

V

CC2

= 5.5V

V

CC2

= 2.5V

LDO Dropout Voltage

vs Load Current

LDO Load Step (10mA to 40mA)

LOAD CURRENT (mA)

0

LDO DROPOUT VOLTAGE (mV)

120

160

200

40

3445 G28

80

40

0

10

20

30

50

≠50

∞C

25

∞C

150

∞C

LDO

OUTPUT

20mV/DIV

LOAD

CURRENT

20mA/DIV

40

µs/DIV

3445 G29

8

LTC3445

3445fa

U

U

U

PI FU CTIO S

V

TRACK

(Pin 1): Supply Sense that V

CC

BATT Tracks when

above 3V. Must be

V

CC1

.

V

BACKUP

(Pin 2): Back-Up Battery Input.

V

CC1

(Pins 3, 10): Power Supply (2.5V to 5.5V). Both V

CC1

pins must be connected externally to the 2.5V to 5.5V

supply.

PGOOD (Pin 4): Fault Report (Undervoltage). Open-drain

driver sinks current whenever LDO1, LDO2 or buck out-

puts are low.

ADD7 (Pin 5): I

2

C Strappable Address (Bit 7)--V

CC1

or

ground.

SDA (Pin 6): I

2

C Data Input.

NC (Pin 7): Not Connected.

SCL (Pin 8): I

2

C Clock Input.

ADD6 (Pin 9): I

2

C Strappable Address (Bit 6)--V

CC1

or

ground.

GND (Pin 11): Buck NFET Ground.

NC (Pin 12): Not Connected.

NC (Pin 13): Not Connected.

SW (Pin 14): Buck Regulator Switch.

RUN (Pin 15): Chip Enable. 1.5V enables the part. Forcing

this pin below 0.3V shuts down the device. In shutdown,

all functions are disabled, drawing <35

µA supply current.

Do not leave RUN floating. Must be

V

CC1

.

NC (Pin 16): Not Connected.

FB (Pin 17): Buck Regulator Feedback.

V

CC

BATT (Pin 18): V

CC

BATT PowerPath Output.

BATTFAULT (Pin 19): Open-Drain Output. It is low when

V

CC1

is low.

LDO1FB (Pin 20): LDO1 Regulator Sense.

LDO1 (Pin 21): LDO1 Regulator Output.

V

CC2

(Pin 22): LDO Regulator Supply Voltage.

LDO2 (Pin 23): LDO2 Regulator Output.

LDO2FB (Pin 24): LDO2 Regulator Sense.

Exposed Pad (Pin 25): Ground. Must be soldered to PCB

ground for electrical contact and optimum thermal

performance.

9

LTC3445

3445fa

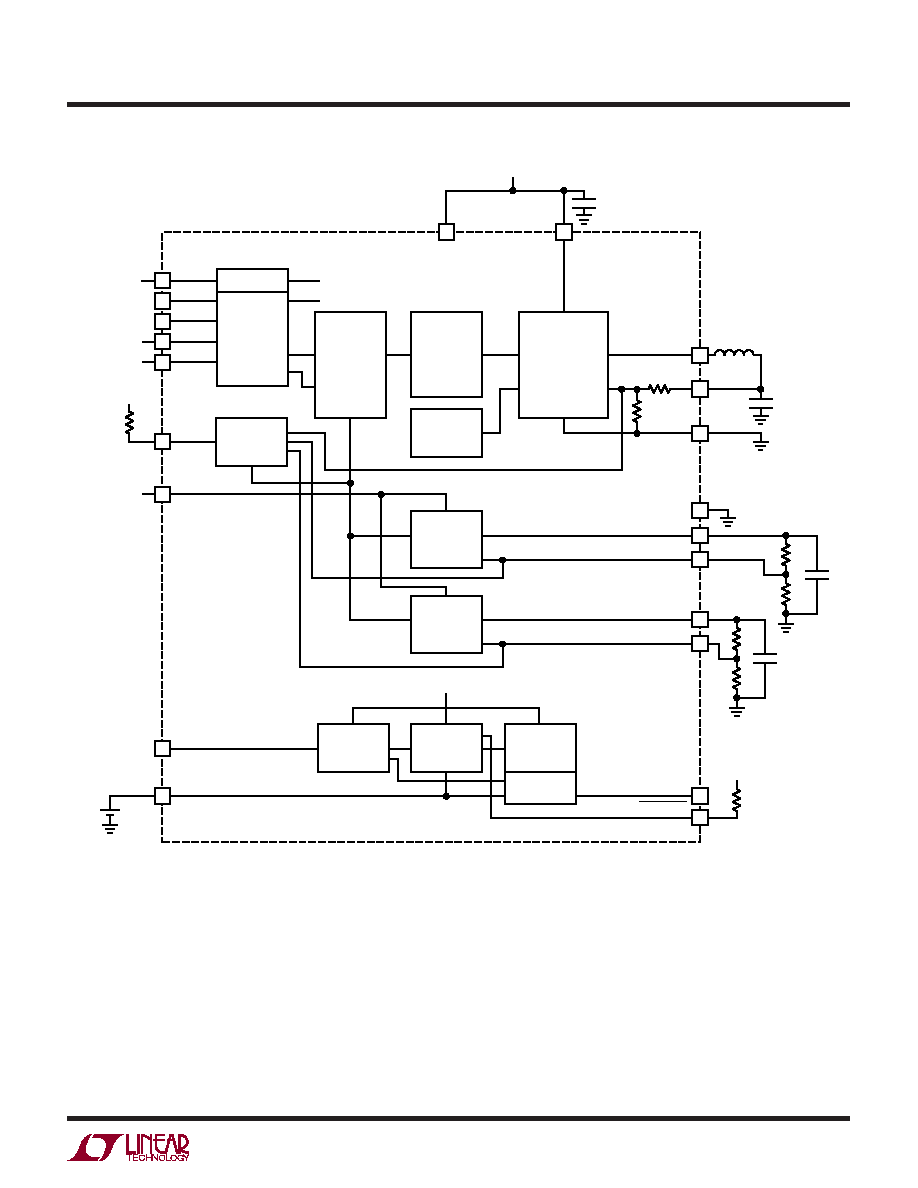

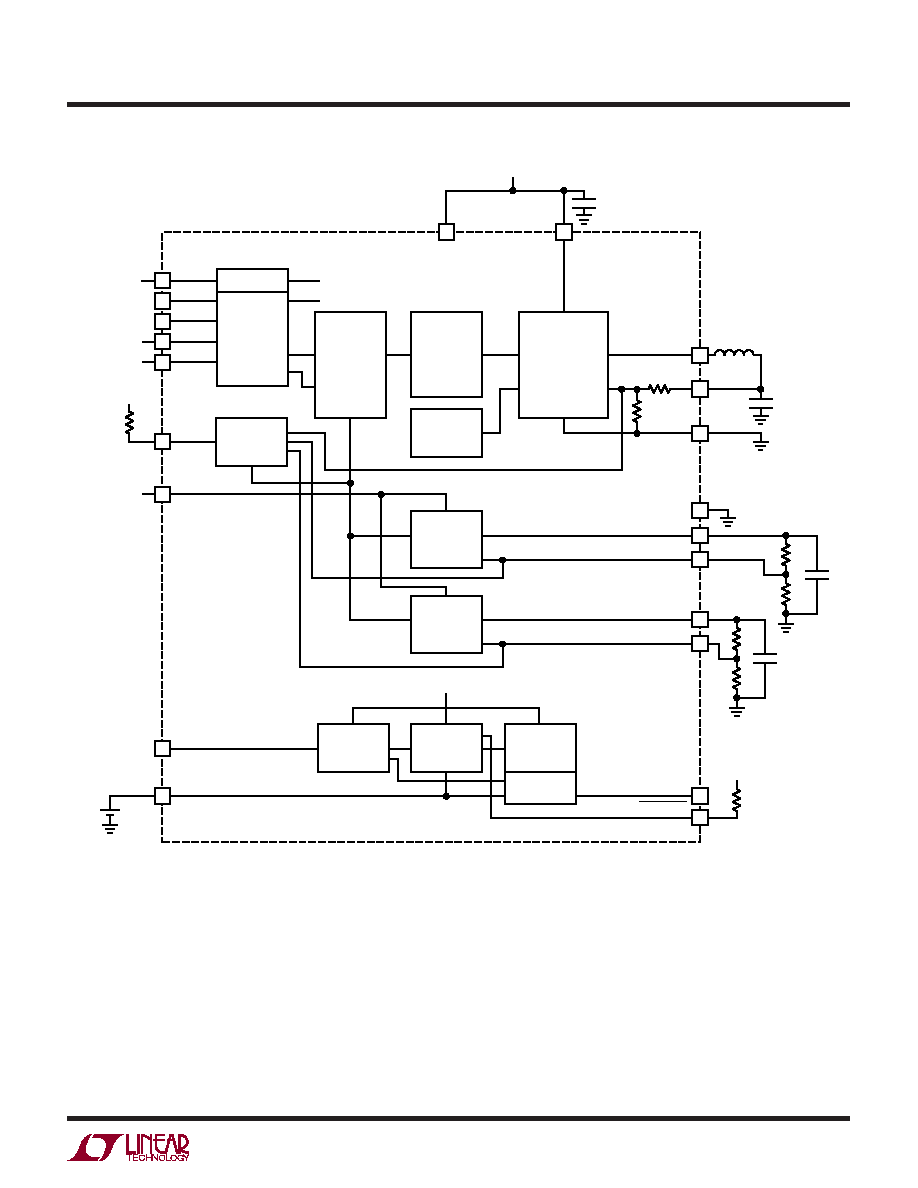

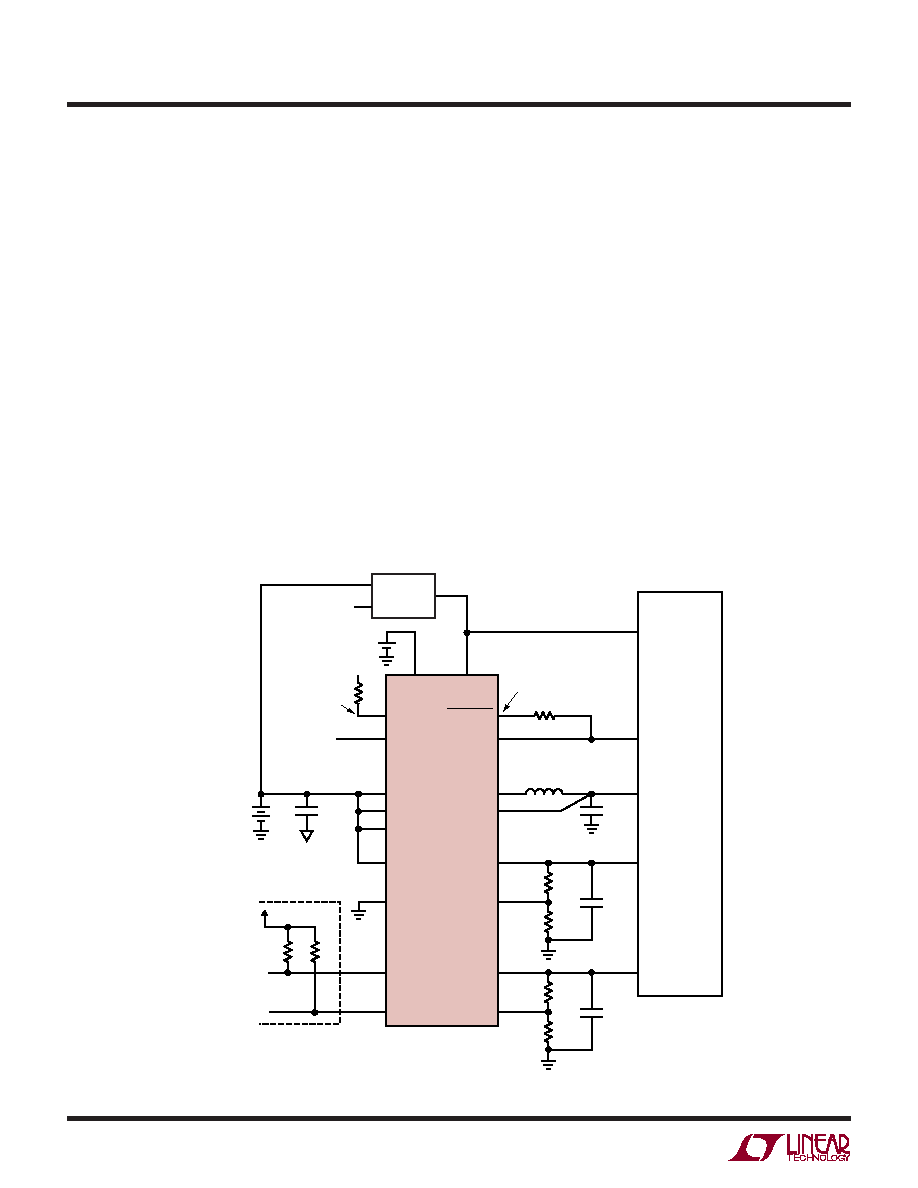

Figure 1

17

14

BUCK REGULATOR

V

REF

SW

OSC ADJUST

3445 F01

FB

SW

15

3

10

RUN

PWR_EN

V

CC1

OR GND

V

CC1

OR GND

6

SDA

8

SCL

5

ADD7

9

ADD6

4

22

PGOOD

V

CC

V

CC

V

CC2

1

V

TRACK

2

V

BACKUP

V

BACKUP

FB

11

GND

21

LDO1 OUT

25

EXPOSED PAD

20

LD01FB

23

LDO2 OUT

24

LD02FB

18

V

CC

BATT

V

BACKUP

19

BATTFAULT

C1

C

IN1

V

CC

C21

C11

R3

R4

GND

SOFT-START

V

CC1

POWER FOR ALL EXCEPT

LDOs AND BUCK PFET

SLEW

CONTROL

V

OUT

CONTROL

STRAPPABLE

STRAPPABLE

BUCK/LDO

ENABLE

BURST

V

REF

DAC

0.6V

SPREAD

SPECTRUM

PowerPath

CONTROL

PowerPath

LDO

POWER

SWITCH

DRIVER

POWER

SWITCH

LDO1

V

CC1

V

CC1

L1

REF

POWER FOR LDOs

OUT

FB

POWER

GOOD

R1

R2

LDO2

REF

OUT

FB

I

2

C

+

3V

COIN

CELL

FU CTIO AL DIAGRA S

U

U

W

10

LTC3445

3445fa

FU CTIO AL DIAGRA S

U

U

W

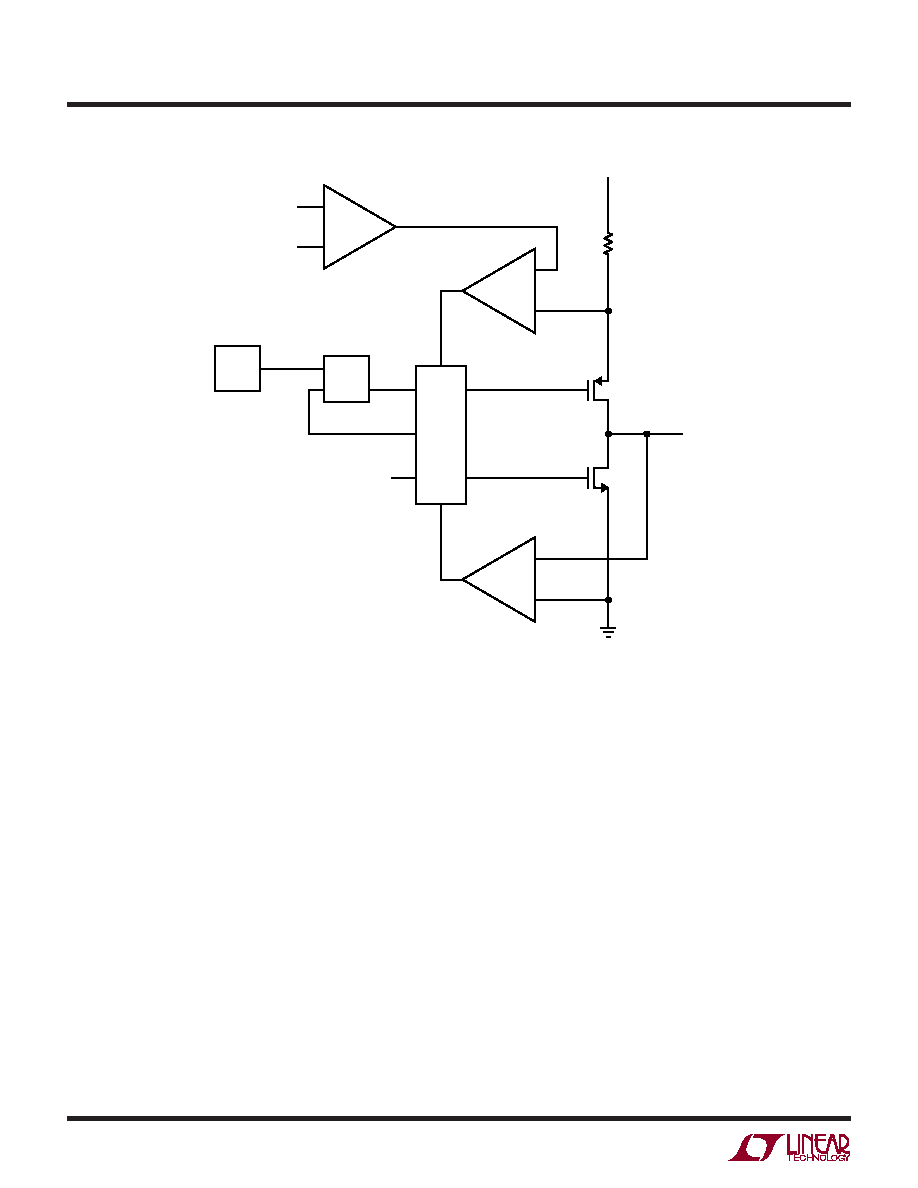

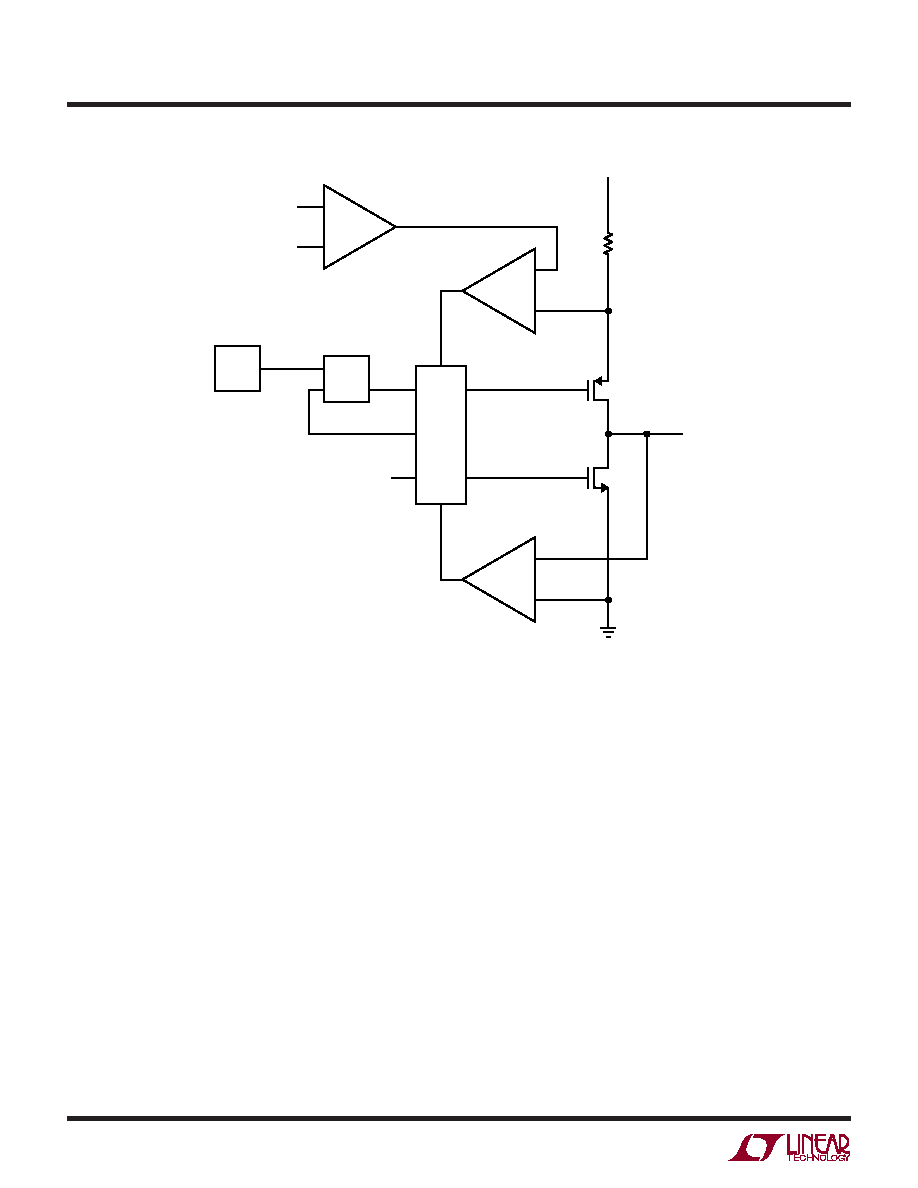

Figure 2. Buck Regulator Detail

V

FB

V

REF

EA

PEAK CURRENT LEVEL REFERENCE

BURST

R

S

SW

PFET

NFET

3445 F02

L

L

V

CC1

I

COMP

I

RCOMP

QB

Q

R

S

LOGIC

OSC

11

LTC3445

3445fa

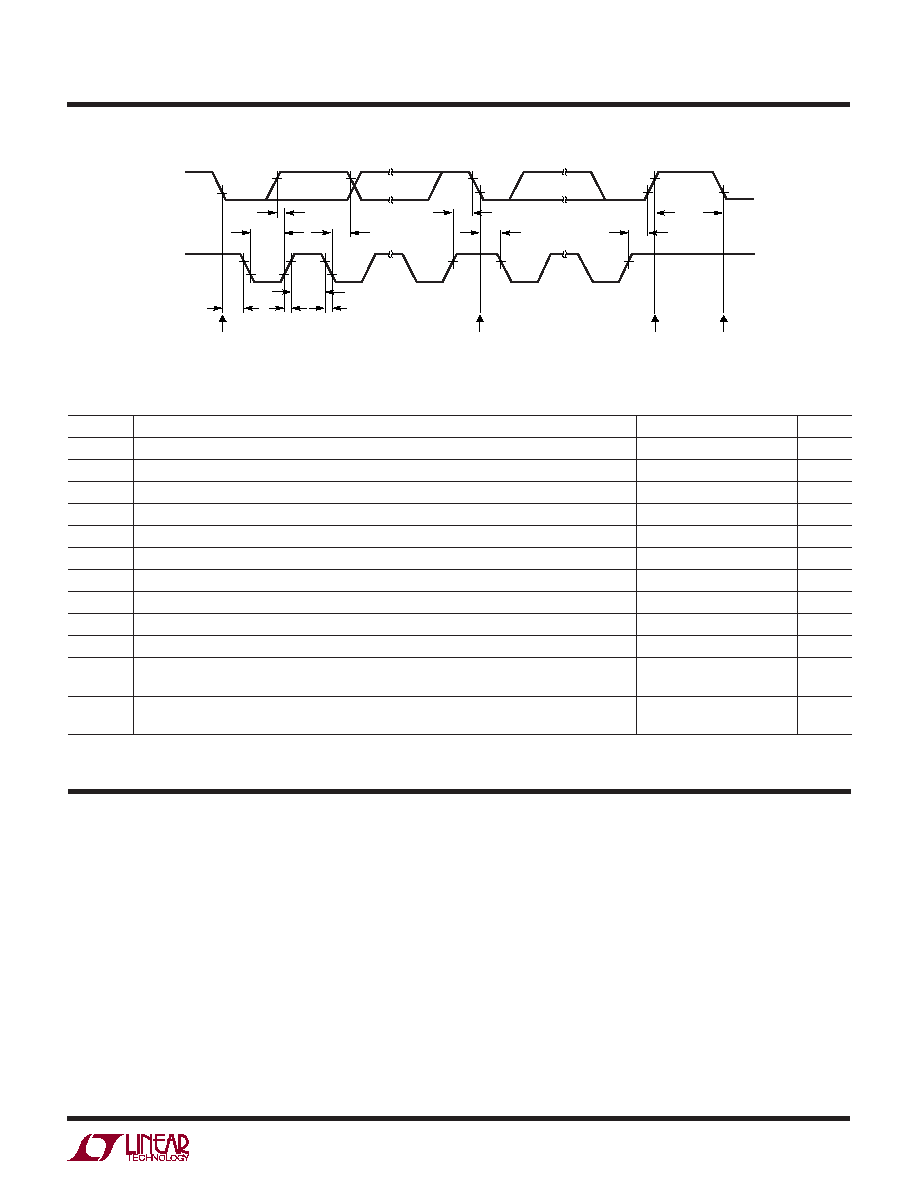

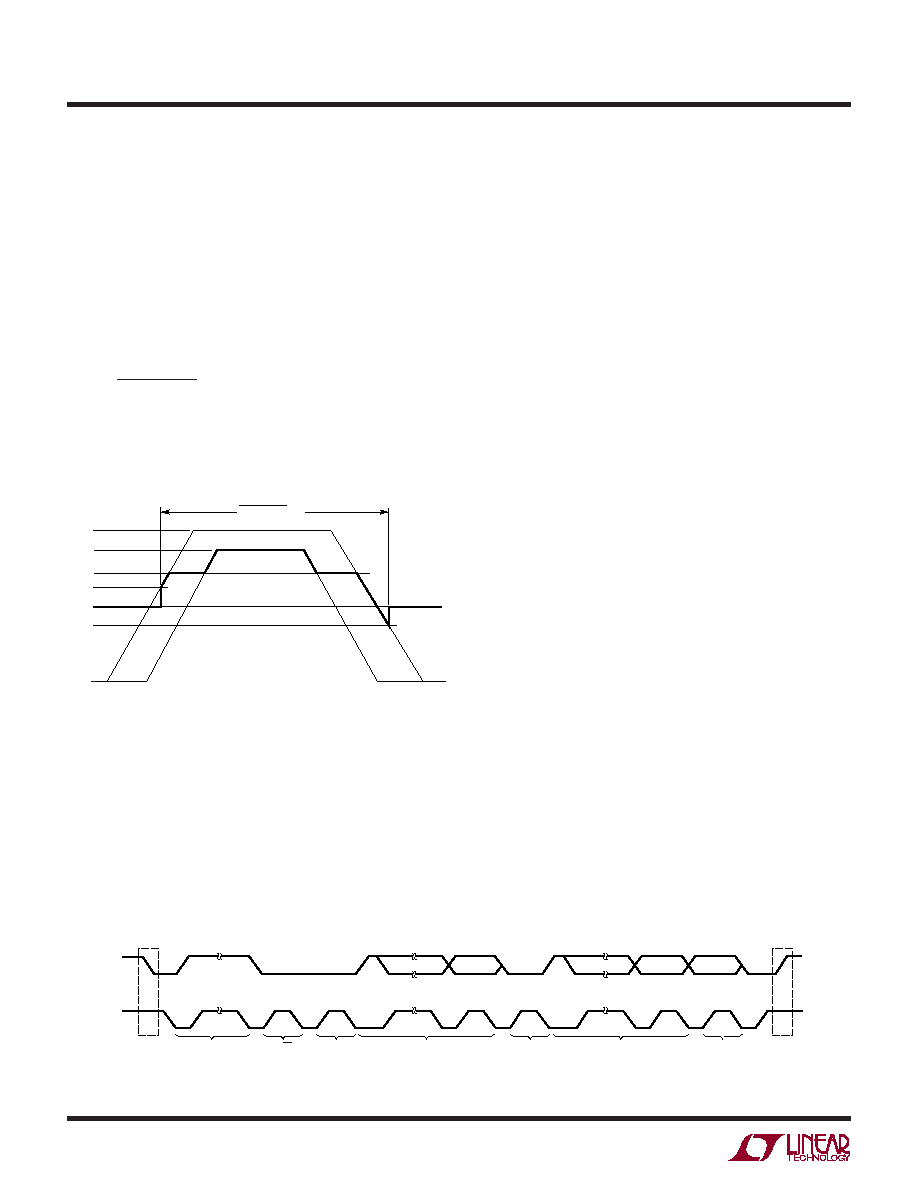

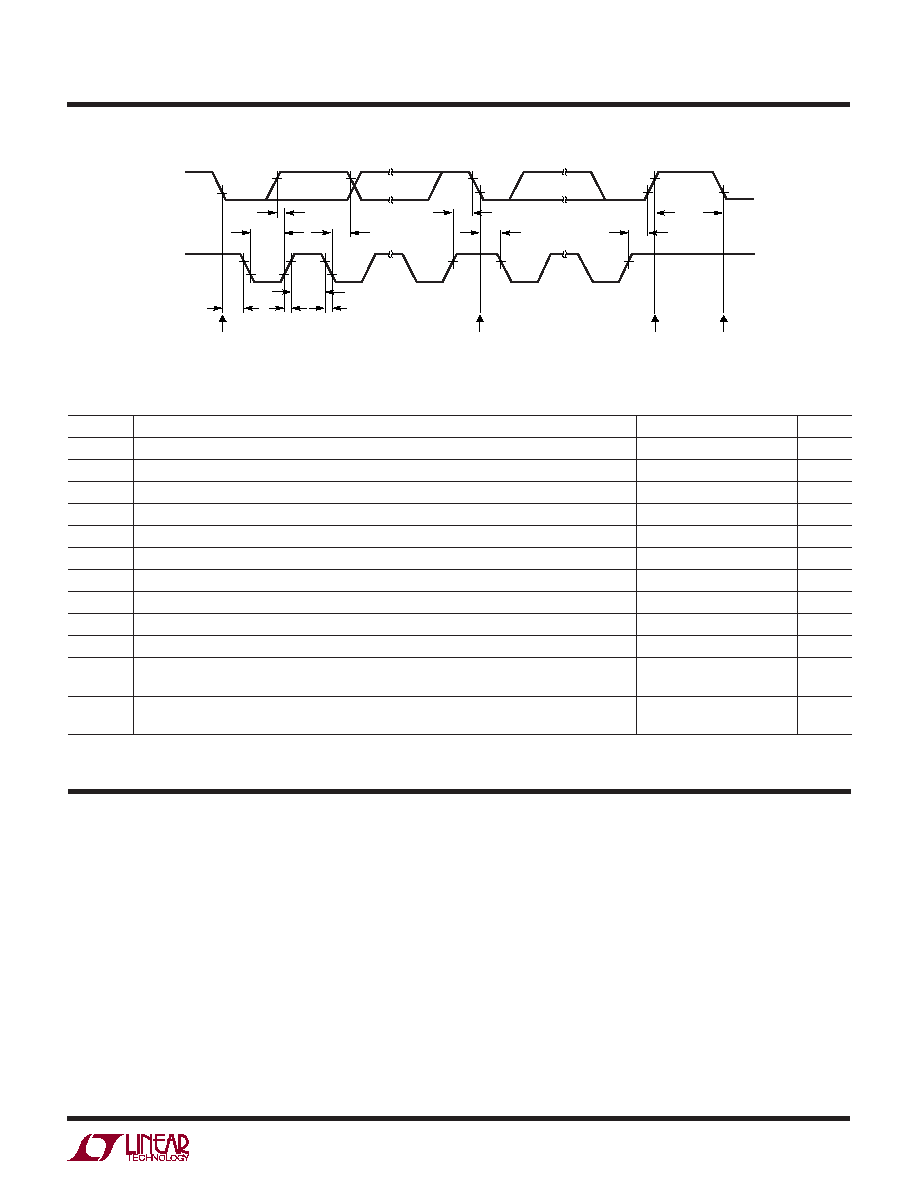

TI I G DIAGRA

U

W

W

t

BUF

t

SUSTO

3445 TD

t

HD(STA)

t

HD(DAT)

t

SU(STA)

t

SU(DAT)

t

LOW

t

HIGH

t

r

t

f

t

HD(STA)

SCL

SDA

START

CONDITION

REPEATED START

CONDITION

STOP

CONDITION

START

CONDITION

I

2

C Fast Mode Timing Specifications (for Reference)

SYMBOL

PARAMETER

MIN

TYP

MAX

UNITS

f

I2C(MAX)

Maximum I

2

C Operating Frequency

0

400

kHz

t

BUF

Bus Free Time Between Stop and Start Condition

1.3

µs

t

HD(RSTA)

Hold Time After (Repeated) Start Condition

0.6

µs

t

SU(RSTA)

Repeated Start Condition Setup Time

0.6

µs

t

SU(STOP)

Stop Condition Setup Time

0.6

µs

t

HD(DAT)

Data Hold Time

0

0.9

ns

t

SU(DAT)

Data Setup Time

100

ns

t

LOW

Clock Low Period

1.3

µs

t

HIGH

Clock High Period

0.6

µs

t

SP

Pulse Width of Spikes Suppressed by Input Filter

0

50

ns

t

f

Clock, Data Fall Time (Note 1)

20 + 0.1

300

ns

∑ C

B

tr

Clock, Data Rise Time (Note 1)

20 + 0.1

300

ns

∑ C

B

Note 1: C

B

= Capacitance of one bus line.

OPERATIO

U

(refer to Figure 1)

BUCK REGULATOR

Main Control Loop

The LTC3445 uses a constant or spread spectrum fre-

quency, current mode step-down architecture (Figure 2).

Both the main (P-channel MOSFET) and synchronous

(N-channel MOSFET) switches are internal. During normal

operation, the internal top power MOSFET is turned on

each cycle when the oscillator sets the RS latch, and

turned off when the current comparator, I

COMP

, resets the

RS latch. The peak inductor current at which I

COMP

resets

the RS latch is controlled by the output of error amplifier

EA. When the load current increases, it causes a slight

decrease in the feedback voltage, FB, relative to an internal

reference voltage, which in turn, causes the EA's output

voltage to increase until the average inductor current

matches the new load current. While the top MOSFET is

off, the bottom MOSFET is turned on until either the

inductor current starts to reverse, as indicated by the

current reversal comparator I

RCMP

, or the beginning of the

next clock cycle.

12

LTC3445

3445fa

OPERATIO

U

Burst Mode Operation

The LTC3445 is capable of Burst Mode operation, in which

the internal power MOSFETs operate intermittently based

on load demand.

In Burst Mode operation, the peak current of the inductor

is set to approximately 200mA regardless of the output load.

Each burst event can last from a few cycles at light loads

to almost continuous cycling with short sleep intervals at

moderate loads. In between these burst events, the power

MOSFETs and any nonessential circuitry are turned off, re-

ducing the buck regulator's quiescent current to 6

µA. In this

sleep state, the load current is being supplied solely from

the output capacitor. As the output voltage droops, the EA's

output rises above the sleep threshold, signaling the BURST

comparator to trip and turn the top MOSFET on. This pro-

cess repeats at a rate that is dependent on the load demand.

Short-Circuit Protection

When the output is shorted to ground, the frequency of the

oscillator is reduced to about 300kHz. This frequency

foldback ensures that the inductor current has more time

to decay, thereby preventing current runaway. The

oscillator's frequency will progressively increase to 1.5MHz

when V

OUT

rises above 0V.

Low Supply Operation

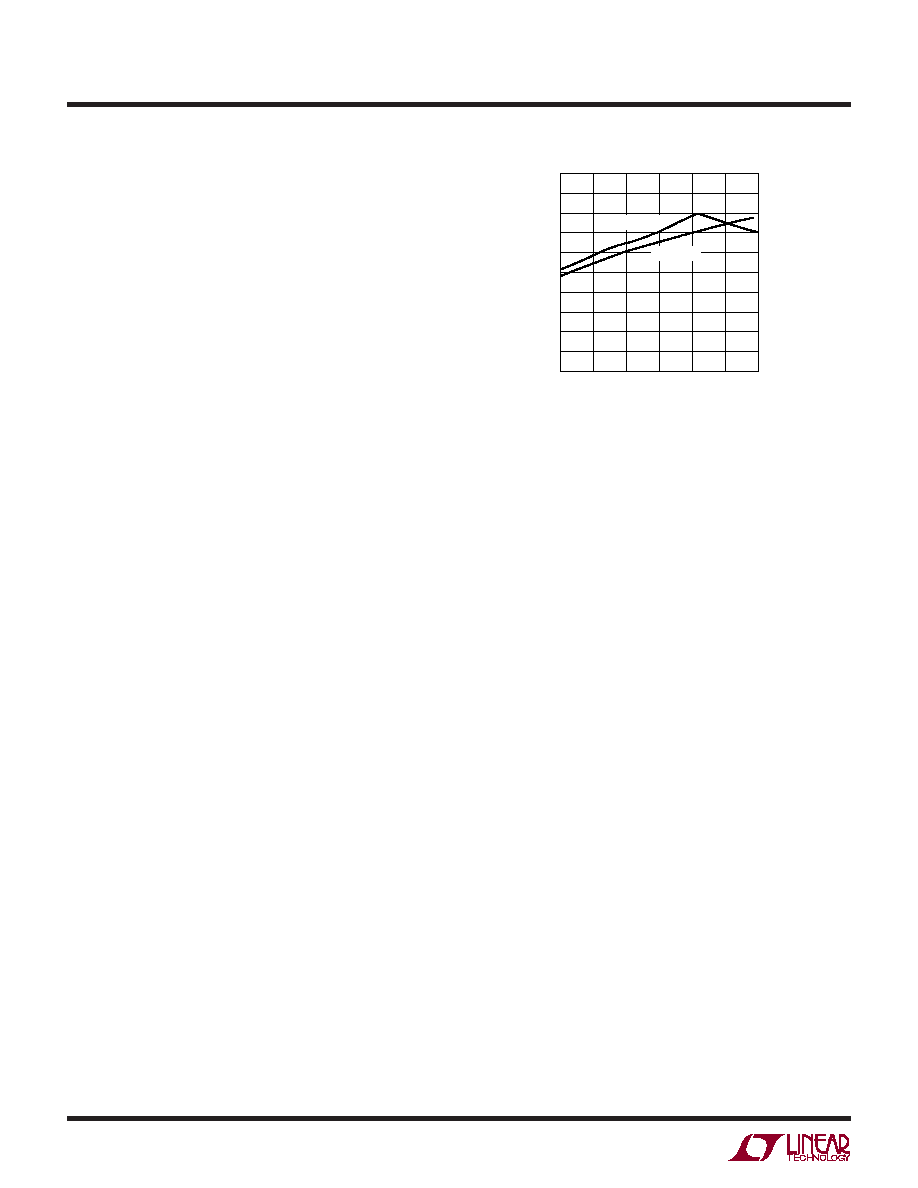

The LTC3445 will operate with input supply voltages as

low as 2.5V, but the maximum allowable output current is

reduced at this low voltage. Figure 3 shows the reduction

in the typical maximum output current as a function of

input voltage for various output voltages.

Slope Compensation and Inductor Peak Current

Slope compensation provides stability in constant fre-

quency architectures by preventing subharmonic oscilla-

tions at high duty cycles. It is accomplished internally by

adding a compensating ramp to the inductor current sig-

nal at duty cycles in excess of 40%. Normally, this results

in a reduction of maximum inductor peak current for duty

cycles >40%. However, the LTC3445 uses a patent-pend-

ing scheme that counteracts this compensating ramp,

which allows the maximum inductor peak current to re-

main unaffected throughout all duty cycles.

(refer to Figure 1)

V

CC1

(V)

2.5

400

MAXIMUM LOAD CURRENT (mA)

600

800

1000

3.5

4.5

3

4

5

3445 F03

1200

1400

500

700

900

1100

1300

5.5

DAC (MIN)

DAC (MAX)

Figure 3. Buck Maximum Peak Current vs V

CC1

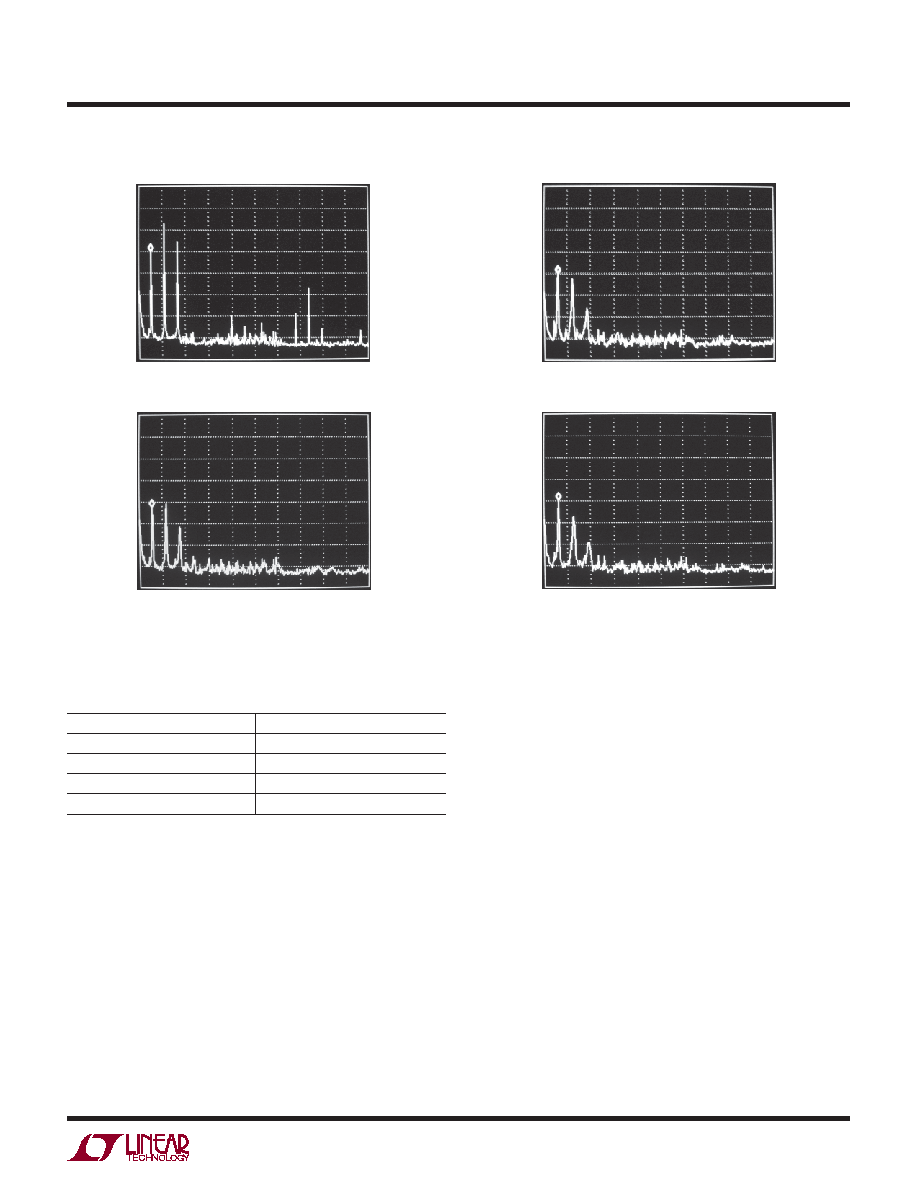

Spread Spectrum

The LTC3445 has a spread spectrum mode that can be

enabled via two register bits. In the spread spectrum

mode, the switching frequency is dithered about a center

frequency of 1.5MHz. Spread spectrum lowers noise at the

regulated output and at the input.

Figure 4 shows the noise reduction capabilities of the

LTC3445 in spread spectrum mode. The percent spread of

the frequency is controlled by two bits in register 5.

00 = 0% Spread

01 = 7.4% Spread

10 = 14.8% Spread

11 = 22.4% Spread

DAC

The buck output voltage is controlled by programming a

6-bit DAC register (REG0[5:0]) and GO bit (REG2[0]). The

output voltage range is 0.85V to 1.55V in ~15mV steps.

The DAC setting range is from 0 to 48. Any settings above

48 will default to the 48 settings value. When the desired

DAC setting is loaded, the GO bit needs to be changed from

0 to 1. Once the GO bit transition occurs, V

OUT

will begin

to change to the DAC setting loaded at that instant.

Slew Rate

A 2-bit register is used to control the rate of change of

V

OUT

between DAC settings. The slew rate is controlled

by stepping V

OUT

to its new setting using a series of

13

LTC3445

3445fa

micro-steps. The table below shows the register settings

and corresponding slew rates.

REG1 [1:0]

SLEW RATE (mV/

µs)

00

11.3

01

7.5

10

3.8

11

0.9

It should be noted that during DAC transistions, PGOOD

fault reporting is disabled.

LDO OPERATION

Adjustable Operation

The LTC3445 contains two 50mA LDOs with an output

voltage range of 0.6V to (V

CC2

≠ 0.3V). The output voltage

is set by the ratio of two external resistors as shown in

Figure 1. Each LDO servos the output voltage (Pin LDOx)

in order to maintain a feedback voltage (Pin LDOxFB) of

0.6V. The current in R1 and R2 is then equal to 0.6V/R2.

The regulated voltage is equal to:

V

OUT

= (0.6V/R2) ∑ (R1+R2)

Frequency Compensation

The LT3445 is frequency compensated by an internal

dominant pole. An output capacitor of 2

µF to 10µF is

usually large enough to provide good stability. In order to

insure stability, a feedforward capacitor may be needed

between the output pin and the feedback pin. This cancels

the pole formed by the stray capacitance in large value

feedback resistors. Also, a feedback capacitor minimizes

noise pickup and improves ripple rejection.

PowerPath OPERATION

The output of the PowerPath (V

CC

BATT) is controlled by

a combination of three inputs: main battery (V

CC1

), V

TRACK

,

and V

BACKUP

.

OPERATIO

U

(refer to Figure 1)

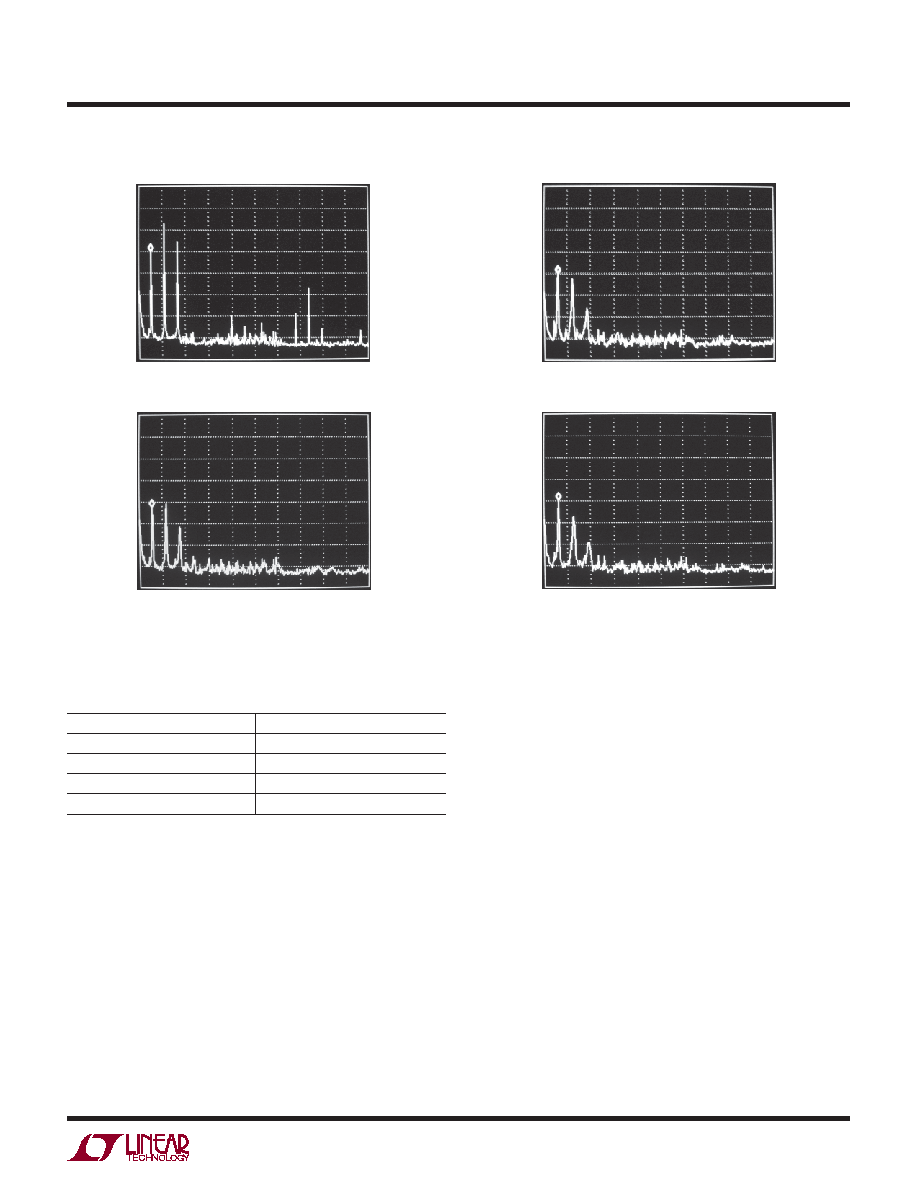

SPR = 00 (Spread Spectrum OFF)

NOISE

10dBm/DIV

SPR = 01

NOISE

10dBm/DIV

START FREQ: 100kHz, RBW: 10kHz, STOP FREQ: 30MHz

START FREQ: 100kHz, RBW: 10kHz, STOP FREQ: 30MHz

SPR = 10

NOISE

10dBm/DIV

SPR = 11

NOISE

10dBm/DIV

START FREQ: 100kHz, RBW: 10kHz, STOP FREQ: 30MHz

START FREQ: 100kHz, RBW: 10kHz, STOP FREQ: 30MHz

Figure 4. LTC3445 Output Noise Spectrum

14

LTC3445

3445fa

When V

CC1

rises above 2.8V, the PowerPath's LDO is

enabled and set to the lesser of 3V or V

CC1

. Once V

TRACK

is 3V or higher, it controls the PowerPath's LDO output

(V

CC

BATT) voltage to within 200mV of V

TRACK

. Note that

V

TRACK

needs to be less than or equal to V

CC1

.

When

V

TRACK

falls below 3V, V

CC1

is used to regulate the

PowerPath's LDO (V

CC

BATT) to 3V. When V

CC1

falls

below 2.4V, the PowerPath LDO is disconnected and

V

BACKUP

is connected to V

CC

BATT.

The PowerPath's fault detection circuit uses an open-drain

driver (BATTFAULT) to report when the main battery is

disconnected.

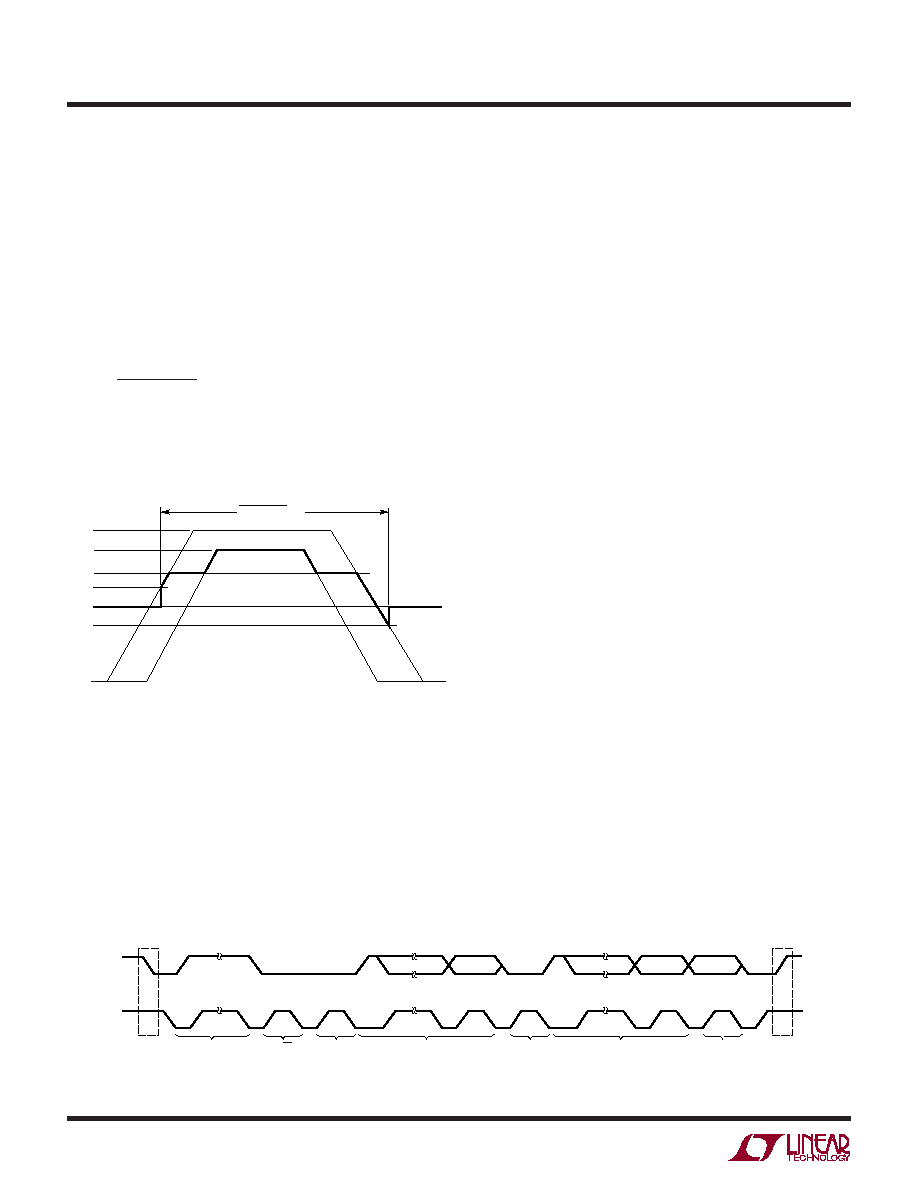

Figure 5 shows the different states of the PowerPath

circuits. Typically, V

BACKUP

is a coin cell; however, other

types of back up power supplies may be used.

General I

2

C Bus/SMBus Description

I

2

C Bus and SMBus are reasonably similar examples of

2-wire, bidirectional, serial communications busses. Call-

ing them 2-wire is not strictly accurate, as there is an

implied third wire, which is the ground line. Large ground

drops or spikes between the grounds of different parts on

the bus can interrupt or disrupt communications, as the

signals on the two wires are both inherently referenced to

a ground which is expected to be common to all parts on

the bus. Both bus types have one data line and one clock

line which are externally pulled to a high voltage when they

are not being controlled by a device on the bus. The

devices on the bus can only pull the data and clock lines

low, which makes it simple to detect if more than one

device is trying to control the bus; eventually, a device will

release a line and it will not pull high because another

device is still holding it low. Pull-ups for the data and clock

lines are usually provided by external discrete resistors,

but external current sources can also be used. Since there

are no dedicated lines to use to tell a given device if another

device is trying to communicate with it, each device must

have a unique address to which it will respond. The first

part of any communication is to send out an address on the

bus and wait to see if another device responds to it. After

a response is detected, meaningful data can be exchanged

between the parts.

Typically, one device will control the clock line at least

most of the time and will normally be sending data to the

other parts and polling them to send data back to it, and

this device is called the master. There can certainly be

more than one master, since there is an effective protocol

to resolve bus contentions, and non-master (slave) de-

vices can also control the clock to delay rising edges and

give themselves more time to complete calculations or

communications (clock stretching). Slave devices need to

OPERATIO

U

(refer to Figure 1)

Figure 6. Typical 2-Wire Serial I

2

C Waveforms

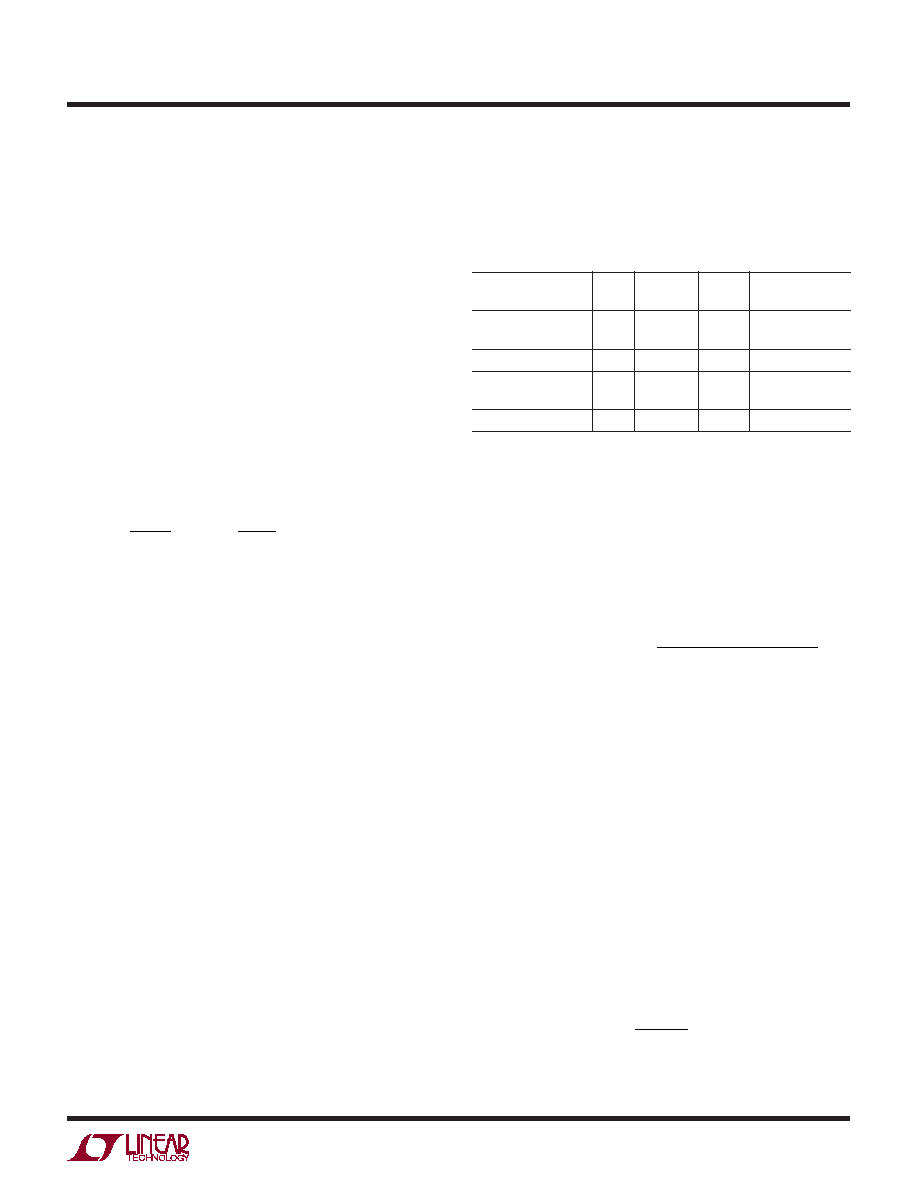

Figure 5

0V

2.4V

2.8V

3V

3.6V

4.2V

V

CC1

V

TRACK

3445 F05

V

BACKUP

BATTFAULT = 1

ADDRESS

START

CONDITION

R/W

1-7

S

SCL

SDA

8

9

1-7

1-7

8

9

3445 F06

8

9

STOP

CONDITION

P

ACK

ACK

ACK

DATA

DATA

I

2

C OPERATION

∑ Simple 2-wire interface

∑ Multiple devices on same bus

∑ Idle bus must have SDA and SCL lines high

∑ LTC3445 is read/write

∑ Master controls bus

∑ Devices listen for unique address that precedes data

15

LTC3445

3445fa

be able to control the data line to acknowledge communi-

cations from the master, and some devices will need to

able to send data back to the master; they will be in control

of the data line while they are doing so. Many slave devices

will have no need to stretch the clock signal and will have

no ability to pull the clock line low, which is the case with

the LTC3445.

Data is exchanged in the form of bytes, which are 8-bit

packets. Any byte needs to be acknowledged by the slave

(data line pulled low) or not acknowledged by the master

(data line left high), so communications are broken up into

9-bit segments, one byte followed by one bit for acknowl-

edging. For example, sending out an address consists of

7 bits of device address, 1 bit that signals whether a read

or write operation will be performed, and then 1 more bit

to allow the slave to acknowledge. There is no theoretical

limit to how many total bytes can be exchanged in a given

transmission.

I

2

C and SMBus are very similar specifications, SMBus

having been derived from I

2

C. In general, SMBus is

targeted to low power devices (particularly battery-pow-

ered ones) and emphasizes low power consumption,

while I

2

C is targeted to higher speed systems where the

power consumption of the bus is not so critical. I

2

C has

three different specifications for three different maximum

speeds, these being standard mode (100kHz max), fast

mode (400kHz max) and HS mode (3.4MHz max). Stan-

dard and fast mode are not radically different, but HS mode

is very different from a hardware and software perspective

and requires an initiating command at standard or fast

speed before data can start transferring at HS speed.

SMBus simply specifies a 100kHz maximum speed.

The START and STOP Conditions

When the bus is not in use, both SCL and SDA must be

high. A bus master signals the beginning of a transmission

with a START condition by transitioning SDA from high to

low while SCL is high. When the master has finished

communicating with the slave, it issues a STOP condition

by transitioning SDA from low to high while SCL is high.

The bus is then free for another transmission.

Acknowledge

The acknowledge signal is used for handshaking between

the master and the slave. An acknowledge signal (LOW

active) as generated by the slave lets the master know that

the latest byte of information was received. The acknowl-

edge-related clock pulse is generated by the master. The

transmitter master releases the SDA line (HIGH) during

the acknowledge clock pulse. The slave receiver must pull

down the SDA line during the acknowledge clock pulse so

that it remains stable LOW during the HIGH period of this

clock pulse.

When a slave receiver doesn't acknowledge the slave

address (for example, it's unable to receive because it's

performing some real-time function), the data line must be

left HIGH by the slave. The master can then generate a

STOP condition to abort the transfer.

If a slave receiver does acknowledge the slave address but,

some time later in the transfer cannot receive any more

data bytes, the master must again abort the transfer. This

is indicated by the slave generating the not acknowledge

on the first byte to follow. The slave leaves the data line

HIGH and the master generates the STOP condition. The

OPERATIO

U

(refer to Figure 1)

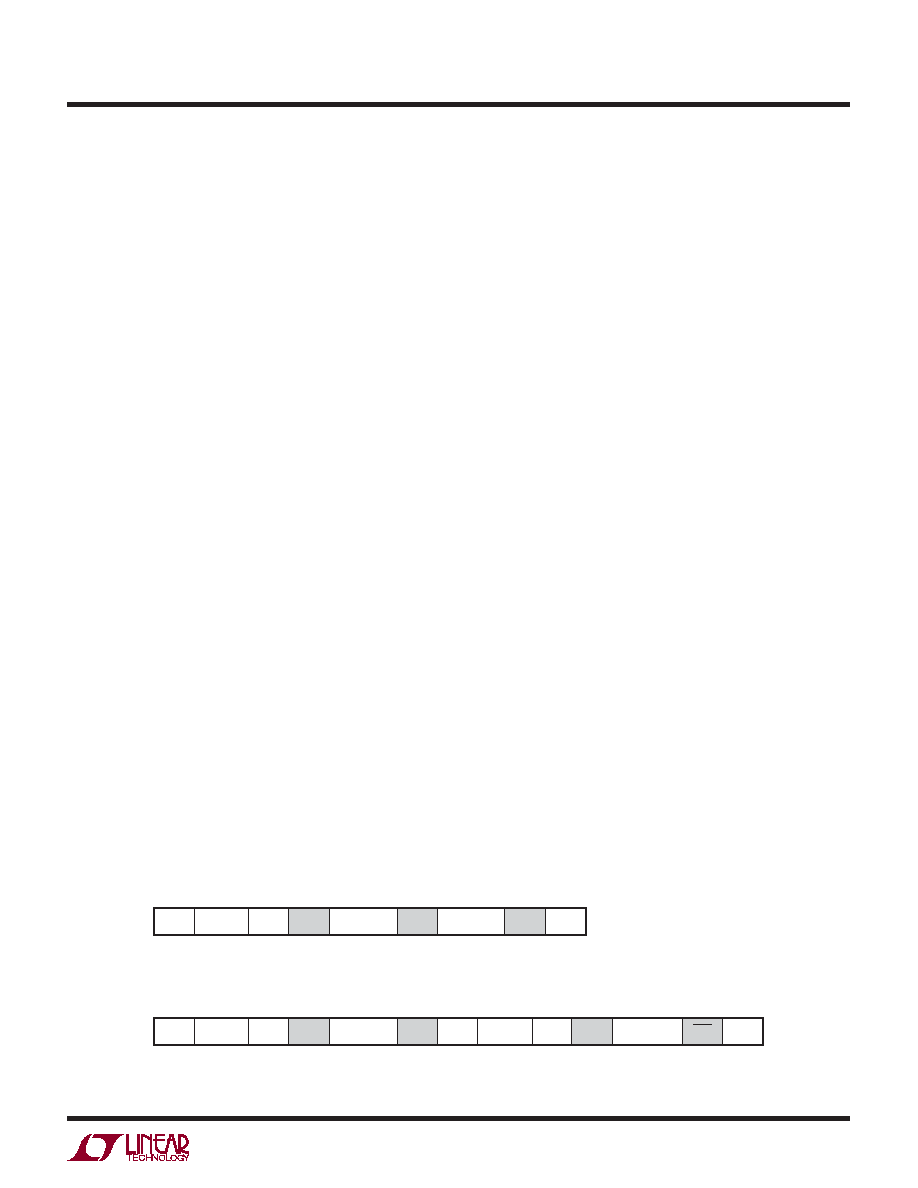

Figure 7

START

WRITE BYTE PROTOCOL

AA01011

XXXXXAAA

WR

ACK

ACK

ACK

STOP

1

1

S

DATA

BYTE

REGISTER

ADDRESS

SLAVE

ADDRESS

0

1

S

0

1

S

0

1

7

1

0

8

8

DDDDDDDD

START

READ BYTE PROTOCOL

AA01011

XXXXXAAA

WR

ACK

ACK

ACK

STOP

1

1

M

3445 G07

DATA

BYTE

REGISTER

ADDRESS

SLAVE

ADDRESS

SLAVE

ADDRESS

1

1

S

0

1

S

0

1

7

1

START

AA01011

1

7

0

RD

ACK

1

S

0

1

1

8

8

DDDDDDDD

16

LTC3445

3445fa

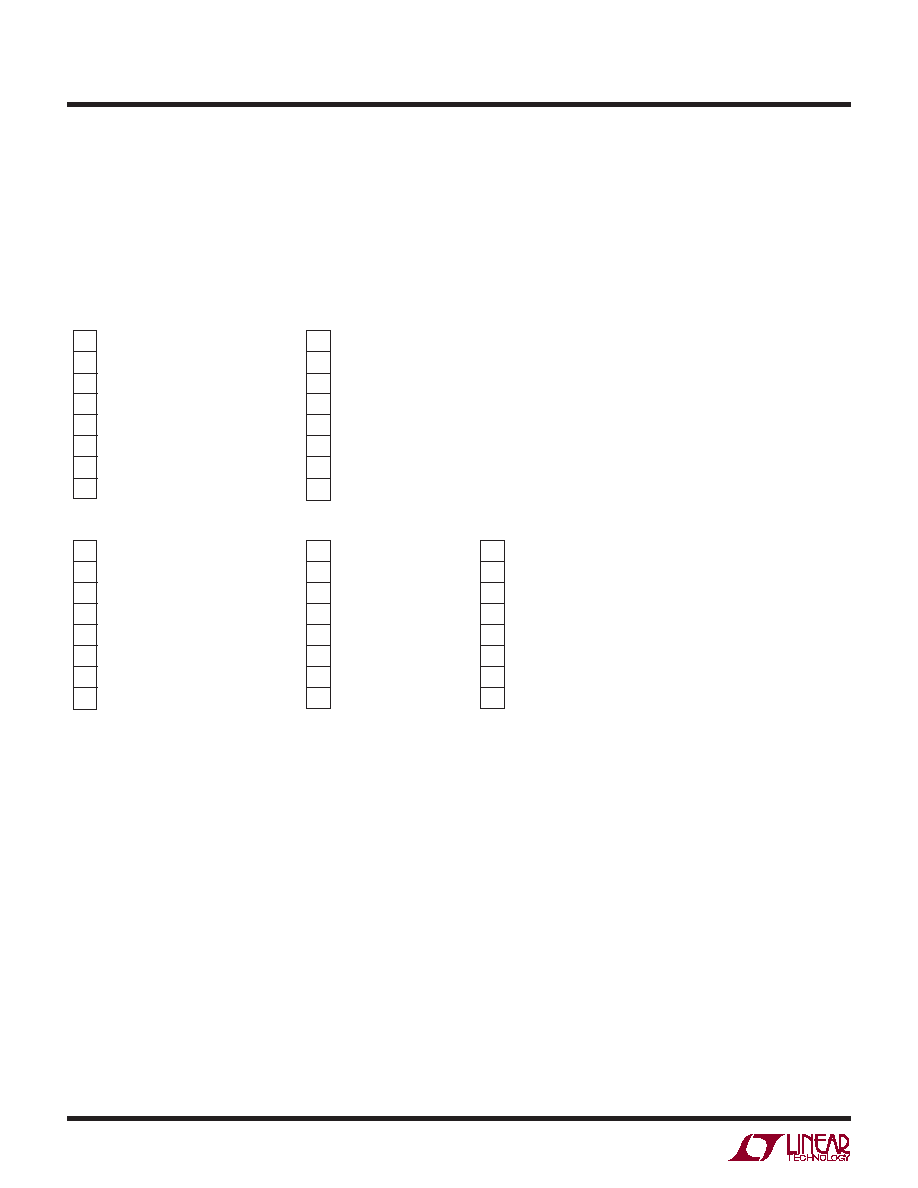

1

2

C Register Definitions

(POR = 00 for all registers)

REG 0

REG 1

7

0 (Logic Low)

7

0 (Logic Low)

6

0 (Logic Low)

6

0 (Logic Low)

5

Buck DAC5

5

0 (Logic Low)

4

Buck DAC4

4

0 (Logic Low)

3

Buck DAC3

3

0 (Logic Low)

2

Buck DAC2

2

0 (Logic Low)

1

Buck DAC1

1

Slew Rate 1

0

Buck DAC0

0

Slew Rate 0

REG 2

REG 3

7

0 (Logic Low)

7

PGOOD Blank Disable

6

0 (Logic Low)

6

0 (Logic Low)

5

0 (Logic Low)

5

0 (Logic Low)

4

STATUS--Buck Thermal Shutdown

4

0 (Logic Low)

3

STATUS--Buck PGOODb

3

BURST Mode

2

STATUS--LDO2 PGOODb

2

LDO2 Disable

1

STATUS--LDO1 PGOODb

1

LDO1 Disable

0

Buck Update (GO Bit)

0

Buck Disable

OPERATIO

U

(refer to Figure 1)

REG 5

7

0 (Logic Low)

6

% SPR1

5

% SPR0

4

(Logic Low)

3

(Logic Low)

2

(Logic Low)

1

(Logic Low)

0

(Logic Low)

data line is also left high by the slave and master after a

slave has transmitted a byte of data to the master in a read

operation, but this is a not-acknowledge that indicates that

the data transfer is successful.

Commands Supported

The LTC3445 supports read byte and write byte com-

mands. For the ACK bits, an S indicates that the slave is

pulling the data line low and an M indicates that the master

is effectively acknowledging by leaving the data line high.

Data Transfer Timing for Write Commands

In order to help assure that bad data is not written into the

part, data from a write command is only stored after a

valid acknowledge has been performed. The part will

detect that SDA is low on the rising edge of SCL that marks

the end of the period in which the LTC3445 acknowledges

the data write and then latch the data during the following

SCL low period.

17

LTC3445

3445fa

APPLICATIO S I FOR ATIO

W

U

U

U

BUCK REGULATOR

The basic LTC3445 application circuit is shown on the first

page of this data sheet. External component selection is

driven by the load requirement and begins with the selec-

tion of L followed by C

IN

and C

OUT

.

Inductor Selection

For most applications, the value of the inductor will fall in

the range of 1

µH to 4.7µH. Its value is chosen based on the

desired ripple current. Large value inductors lower ripple

current and small value inductors result in higher ripple

currents. Higher V

CC1

or lower V

OUT

also increases the

ripple current as shown in Equation 1. A reasonable

starting point for setting ripple current is

I

L

= 240mA

(40% of 600mA).

=

( )( )

I

f L

V

V

V

L

OUT

OUT

CC

1

1

1

≠

(1)

The DC current rating of the inductor should be at least

equal to the maximum load current plus half the ripple

current to prevent core saturation. Thus, a 720mA rated

inductor should be enough for most applications (600mA

+ 120mA). For better efficiency, choose a low DC-resis-

tance inductor.

The inductor value also has an effect on Burst Mode

operation. The transition to low current operation begins

when the inductor current peaks fall to approximately

200mA. Lower inductor values (higher

I

L

) will cause this

to occur at lower load currents, which can cause a dip in

efficiency in the upper range of low current operation. In

Burst Mode operation, lower inductance values will cause

the burst frequency to increase.

Inductor Core Selection

Different core materials and shapes will change the size/

current and price/current relationship of an inductor.

Toroid or shielded pot cores in ferrite or permalloy mate-

rials are small and don't radiate much energy, but gener-

ally cost more than powdered iron core inductors with

similar electrical characteristics. The choice of which style

inductor to use often depends more on the price vs size

requirements and any radiated field/EMI requirements

than on what the LTC3445 requires to operate. Table 1

shows some typical surface mount inductors that work

well in LTC3445 applications.

Table 1

MANUFACTURER

VALUE

DCR

MAX DC

SIZE

PART NUMBER

(

µH) (m MAX)

(A)

L

◊ W ◊ H (mm

3

)

Sumida CDRH3D16/

2.2

72

1.2

4.0

◊ 4.0 ◊ 1.8

HP2R2

Sumida CR434R7

4.7

109

1.15

4.0

◊ 4.5 ◊ 3.5

TDK TDK7030T-

2.2

12

5.5

7.3

◊ 6.8 ◊ 3.2

2R2M5R4

Coilcraft D03316P-222

2.2

12

7

12.45

◊ 9.4 ◊ 5.21

C

IN

and C

OUT

Selection

In continuous mode, the source current of the top MOSFET

is a square wave of duty cycle V

OUT

/V

CC1

. To prevent large

voltage transients, a low ESR input capacitor sized for the

maximum RMS current must be used. The maximum

RMS capacitor current is given by:

C

I

V

V

V

V

IN

OMAX

OUT

CC

OUT

CC

required I

RMS

(

)

[

]

1

1 2

1

≠

/

(2)

This formula has a maximum at V

CC1

= 2V

OUT

, where I

RMS

= I

OUT

/2. This simple worst-case condition is commonly

used for design because even significant deviations do not

offer much relief. Note that the capacitor manufacturer's

ripple current ratings are often based on 2000 hours of life.

This makes it advisable to further derate the capacitor, or

choose a capacitor rated at a higher temperature than

required. Always consult the manufacturer if there is any

question.

The selection of C

OUT

is driven by the required effective

series resistance (ESR). Typically, once the ESR require-

ment for C

OUT

has been met, the RMS current rating

generally far exceeds the I

RIPPLE(P-P)

requirement. The

output ripple

V

OUT

is determined by:

+

V

I ESR

fC

OUT

L

OUT

1

8

(3)

18

LTC3445

3445fa

where f = operating frequency, C

OUT

= output capacitance

and

I

L

= ripple current in the inductor. For a fixed output

voltage, the output ripple is highest at maximum input

voltage since

I

L

increases with input voltage.

Aluminum electrolytic and dry tantalum capacitors are

both available in surface mount configurations. In the case

of tantalum, it is critical that the capacitors are surge tested

for use in switching power supplies. An excellent choice is

the AVX TPS series of surface mount tantalum. These are

specially constructed and tested for low ESR so they give

the lowest ESR for a given volume. Other capacitor types

include Sanyo POSCAP, Kemet T510 and T495 series, and

Sprague 593D and 595D series. Consult the manufacturer

for other specific recommendations.

Using Ceramic Input and Output Capacitors

Higher values, lower cost ceramic capacitors are now

becoming available in smaller case sizes. Their high ripple

current, high voltage rating and low ESR make them ideal

for switching regulator applications. Because the

LTC3445's control loop does not depend on the output

capacitor's ESR for stable operation, ceramic capacitors

can be used freely to achieve very low output ripple and

small circuit size.

However, care must be taken when ceramic capacitors are

used at the input and the output. When a ceramic capacitor

is used at the input and the power is supplied by a wall

adapter through long wires, a load step at the output can

induce ringing at the input, V

CC1

. At best, this ringing can

couple to the output and be mistaken as loop instability. At

worst, a sudden inrush of current through the long wires

can potentially cause a voltage spike at V

CC1

, large enough

to damage the part.

When choosing the input and output ceramic capacitors,

choose the X5R or X7R dielectric formulations. These

dielectrics have the best temperature and voltage charac-

teristics of all the ceramics for a given value and size.

Buck Output Voltage Programming

The LTC3445 has an internal resistor divider network tied

to the FB pin. The output voltage is controlled by a DAC

(6-bit register) whose setting is controlled by the I

2

C

interface. The effective DAC bit range is from 0 to 48. Note

that any DAC settings above 48 defaults to the 48 setting.

The DAC controls the V

OUT

range of 0.85V to 1.55V in

~15mV steps. The default value for V

OUT

is 1.35V and is

reset to this value whenever V

CC1

comes up.

When the DAC's value is changed, LTC3445 controls

V

OUT

's slew rate via a 2-bit RATE register. The RATE

register can be updated via the I

2

C interface. The slew rate

can be set to approximately 0.9mV/

µs, 3.8mV/µs, 7.5mV/µs

or 11.3mV/

µs. The default value for RATE is 10mV/µs and

is reset to this value whenever V

CC1

comes up.

The DAC and RATE values are not lost whenever the RUN

pin is deasserted.

Once the DAC and RATE registers are programmed, a GO

bit transition is required for the buck to update. This is

accomplished by changing the GO bit (REG2[0]) from

logic low to a logic high.

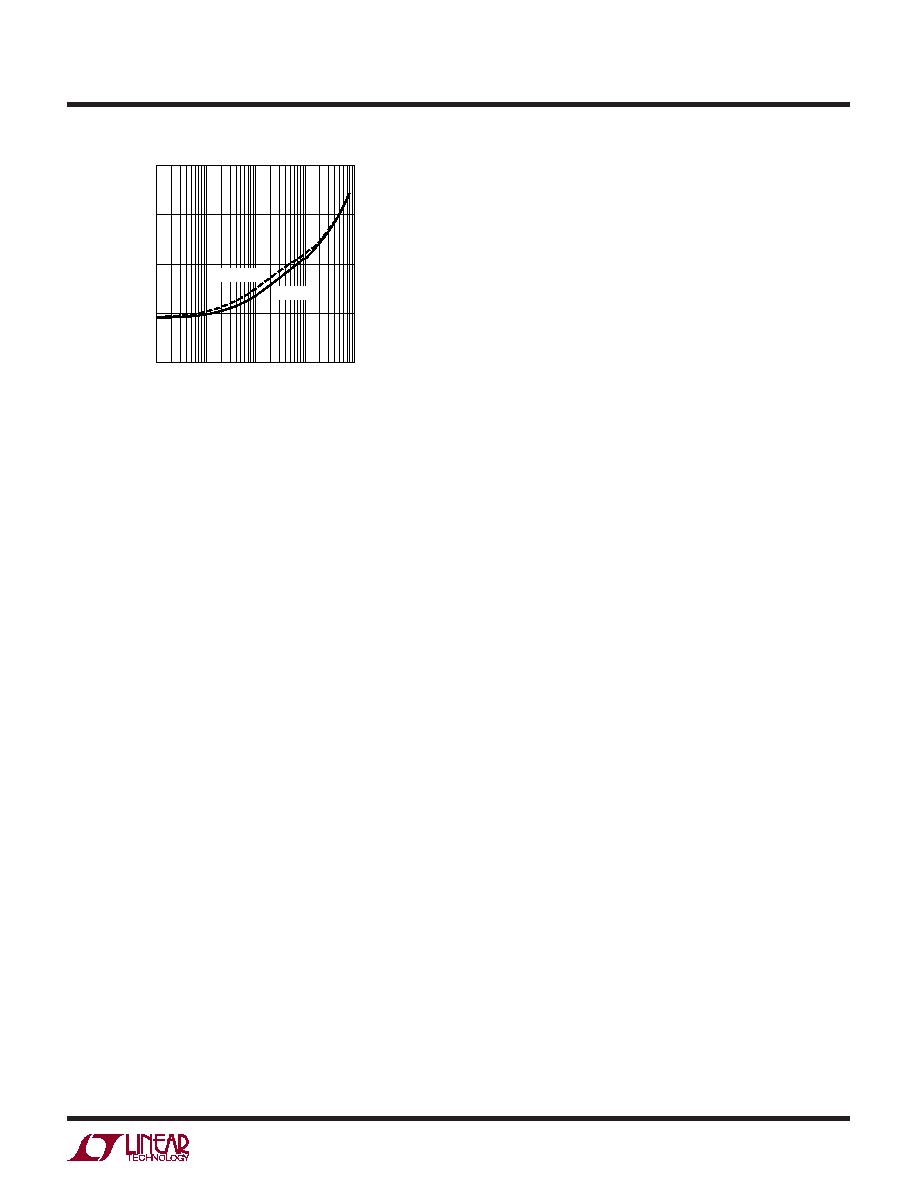

Efficiency Considerations

The efficiency of a switching regulator is equal to the

output power divided by the input power times 100%. It is

often useful to analyze individual losses to determine what

is limiting the efficiency and which change would produce

the most improvement. Efficiency can be expressed as:

Efficiency = 100% ≠ (L1 + L2 + L3 + ...)

where L1, L2, etc. are the individual losses as a percentage

of input power.

Although all dissipative elements in the circuit produce

losses, two main sources usually account for most of the

losses in LTC3445 buck regulator circuits: V

CC1

quiescent

current and I

2

R losses. The V

CC1

quiescent current loss

dominates the efficiency loss at very low load currents

whereas the I

2

R loss dominates the efficiency loss at

medium to high load currents. In a typical efficiency plot,

the efficiency curve at very low load currents can be

misleading since the actual power lost is of no conse-

quence as illustrated in Figure 8.

1. The V

CC1

quiescent current is due to two components:

the DC bias current as given in the Electrical Character-

istics and the internal main switch and synchronous

switch gate charge currents. The gate charge current

results from switching the gate capacitance of the

APPLICATIO S I FOR ATIO

W

U

U

U

19

LTC3445

3445fa

Checking Transient Response

The regulator loop response can be checked by looking at

the load transient response. Switching regulators take

several cycles to respond to a step in load current. When

a load step occurs, V

OUT

immediately shifts by an amount

equal to (

I

LOAD

∑ ESR), where ESR is the effective series

resistance of C

OUT

.

I

LOAD

also begins to charge or

discharge C

OUT

, which generates a feedback error signal.

The regulator loop then acts to return V

OUT

to its steady-

state value. During this recovery time V

OUT

can be moni-

tored for overshoot or ringing that would indicate a stability

problem. For a detailed explanation of switching control

loop theory, see Application Note 76.

A second, more severe transient is caused by switching in

loads with large (>1

µF) supply bypass capacitors. The

discharged bypass capacitors are effectively put in parallel

with C

OUT

, causing a rapid drop in V

OUT

. No regulator can

deliver enough current to prevent this problem if the load

switch resistance is low and it is driven quickly. The only

solution is to limit the rise time of the switch drive so that

the load rise time is limited to approximately (25 ∑ C

LOAD

).

Thus, a 10

µF capacitor charging to 3.3V would require a

250

µs rise time, limiting the charging current to about

130mA.

LDO REGULATORS

The LDOs in the LTC3445 are 50mA low dropout regula-

tors with low quiescent and shutdown currents. Each

device is capable of supplying 50mA at a dropout voltage

of 300mV. The LDOs are current limited to greater than

50mA but less than 75mA. The output voltages of the

LDOs are set with external resistive dividers according to

the following formula:

V

LDOOUT1

= 0.6(1 + R1/R2)

(4)

V

LDOOUT2

= 0.6(1 + R3/R4)

(5)

Output Capacitance and Transient Response

The LTC3445 LDOs are designed to be stable with a wide

range of output capacitors. A minimum output capacitor

of 2.2

µF with an ESR of 3 or less is recommended to

internal power MOSFET switches. Each time the gate is

switched from high to low to high again, a packet of

charge, dQ, moves from V

CC1

to ground. The resulting

dQ/dt is the current out of V

CC1

that is typically larger

than the DC bias current. In continuous mode, I

GATECHG

= f(Q

T

+ Q

B

) where Q

T

and Q

B

are the gate charges of the

internal top and bottom switches. Both the DC bias and

gate charge losses are proportional to V

CC1

and thus

their effects will be more pronounced at higher supply

voltages.

2. I

2

R losses are calculated from the resistances of the

internal switches, R

SW

, and external inductor R

L

. In

continuous mode, the average output current flowing

through inductor L is "chopped" between the main

switch and the synchronous switch. Thus, the series

resistance looking into the SW pin is a function of both

top and bottom MOSFET R

DS(ON)

and the duty cycle

(DC) as follows:

R

SW

= (R

DS(ON)TOP

)(DC) + (R

DS(ON)BOT

)(1 ≠ DC)

The R

DS(ON)

for both the top and bottom MOSFETs can

be obtained from the Typical Performance Charateristics

curves. Thus, to obtain I

2

R losses, simply add R

SW

to

R

L

and multiply the result by the square of the average

output current.

Other losses including C

IN

and C

OUT

ESR dissipative

losses and inductor core losses generally account for

less than 2% total additional loss.

APPLICATIO S I FOR ATIO

W

U

U

U

Figure 8. Power Loss vs Load Current, V

CC1

= 3.6V

LOAD CURRENT (mA)

1

POWER LOSS (mW)

10

100

1000

0.1

10

100

1000

3445 F08

0.1

1

DAC MIN

DAC MAX

20

LTC3445

3445fa

prevent oscillations. The LTC3445 LDOs are micropower

devices and output transient response will be a function of

output capacitance. Larger values of output capacitance

decrease the peak deviations and provide improved tran-

sient response for larger load current changes.

PowerPath CONTROLLER

The PowerPath circuitry in the LTC3445 is used to provide

backup power from V

BACKUP

to the V

CC

BATT pin when

V

CC1

is low or disconnected. When V

CC1

is below 2.8V, the

PowerPath routes V

BACKUP

, typically a coin cell, to the V

CC

BATT pin. While V

BACKUP

is selected there is no current

limiting except for a small (<5

) resistance from the

V

BACKUP

input to the V

CC

BATT output. The LTC3445 sinks

less than 6.5

µA from V

BACKUP

when it is selected and sinks

less than 0.1

µA from V

BACKUP

when it is not selected.

When V

CC1

exceeds 2.8V, V

BACKUP

is disconnected from

V

CC

BATT and an internal LDO regulates the V

CC

BATT

voltage to the minimum of V

CC1

or typically 3V. The

internal LDO is current limited to less than 50mA, but

greater than 10mA. Capacitance on the V

CC

BATT pin

should be at least 2

µF with an ESR less than 3.

V

BACKUP

will be routed to the V

CC

BATT output when the

main battery voltage falls below 2.4V. As the main battery,

V

CC1

, voltage drops from 3V to 2.4V, the LDO will be in

dropout, V

CC

BATT will follow V

CC1

down, rebounding to

V

BACKUP

when V

CC1

falls below 2.4V. If V

CC1

is removed

quickly, the capacitor on V

CC

BATT will limit the V

CC

BATT

droop until V

BACKUP

is switched in.

The V

TRACK

input offers the capability of the V

CC

BATT

voltage to follow the voltage on V

TRACK

up to V

CC1

. In

effect, V

TRACK

overrides the internal reference of the LDO,

resulting in the LDO output (V

CC

BATT) having a gain of 1

relative to V

TRACK

once V

TRACK

exceeds a typical value of

3V. V

CC

BATT will follow V

TRACK

to within 200mV provid-

ing V

TRACK

does not exceed the dropout voltage of the

LDO, which is powered by V

CC1

.

V

BACKUP

should be present prior to V

CC1

being connected.

V

BACKUP

provides power to the BATTFAULT driver which

APPLICATIO S I FOR ATIO

W

U

U

U

is used to detect an absent or low V

CC1

. If V

BACKUP

is not

present, the LTC3445 will be unable to pull the BATTFAULT

pin low to signal a V

CC1

fault condition.

Output Capacitance and Transient Response

The LDO used LTC3445 PowerPath is designed to be

stable with a wide range of output capacitors. A minimum

output capacitor of 2.2

µF with an ESR of 3 or less is

recommended to prevent oscillations. The LTC3445

PowerPath LDO is a micropower device and output tran-

sient response will be a function of output capacitance.

Larger values of output capacitance decrease the peak

deviations and provide improved transient response for

larger load current changes.

THERMAL CONSIDERATIONS

In most applications the LTC3445 does not dissipate

much heat due to its high efficiency. But, in applications

where the LTC3445 is running at high ambient tempera-

ture with low supply voltage and high duty cycles, such as

in dropout, the heat dissipated may exceed the maximum

junction temperature of the part. If the junction tempera-

ture reaches approximately 150

∞C, both power switches

will be turned off and the SW node will become high

impedance. The remaining regulators will also turn off.

To ensure the LTC3445 doesn't exceed the maximum

junction temperature, the user will need to do some

thermal analysis. The goal of the thermal analysis is to

determine whether the power dissipated exceeds the

maximum junction temperature of the part. The tempera-

ture rise is given by:

T

R

=

JA

∑ (PD

BUCK

+ PD

LDO1

+ PD

LDO2

+ PD

PowerPath

)

where P

D

is the power dissipated by the regulator and

JA

is the thermal resistance from the junction of the die to the

ambient temperature.

The junction temperature, T

J

, is given by:

T

J

= T

A

+ T

R

where T

A

is the ambient temperature.

21

LTC3445

3445fa

As an example, consider the LTC3445 in dropout at an

input voltage of 2.7V, an ambient temperature of 70

∞C, a

buck load current of 600mA, LDO1 set to 1.3V with a load

of 25mA, LDO2 set to 1.1V with a load of 15mA, and the

PowerPath regulator at 2.5V with a load of 6

µA. From the

typical performance graph of switch resistance, the R

DS(ON)

of the P-channel switch at 70

∞C is approximately 0.52.

Therefore, power dissipated by the part is:

P

D(BUCK)

= I

LOAD

2

∑ R

DS(ON)

= 180mW

P

D(LDO1)

= (2.7 ≠ 1.3)V ∑ 0.025A = 35mW

P

D(LDO2)

= (2.7 ≠ 1.1)V ∑ 0.015A = 24mW

P

D(PowerPath)

= (2.7 ≠ 2.5)V ∑ 6

µA = 1.2µW

P

D(TOTAL)

= 0.239W

For the QFN24 package, the

JA

is 37

∞C/W. Thus, the

junction temperature of the regulator is:

T

J

= 70

∞C + (0.239)(37) = 78.8∞C

which is well below the maximum junction temperature of

125

∞C. Note that at higher supply voltages, the junction

temperature is lower due to reduced switch resistance

(R

DS(ON)

).

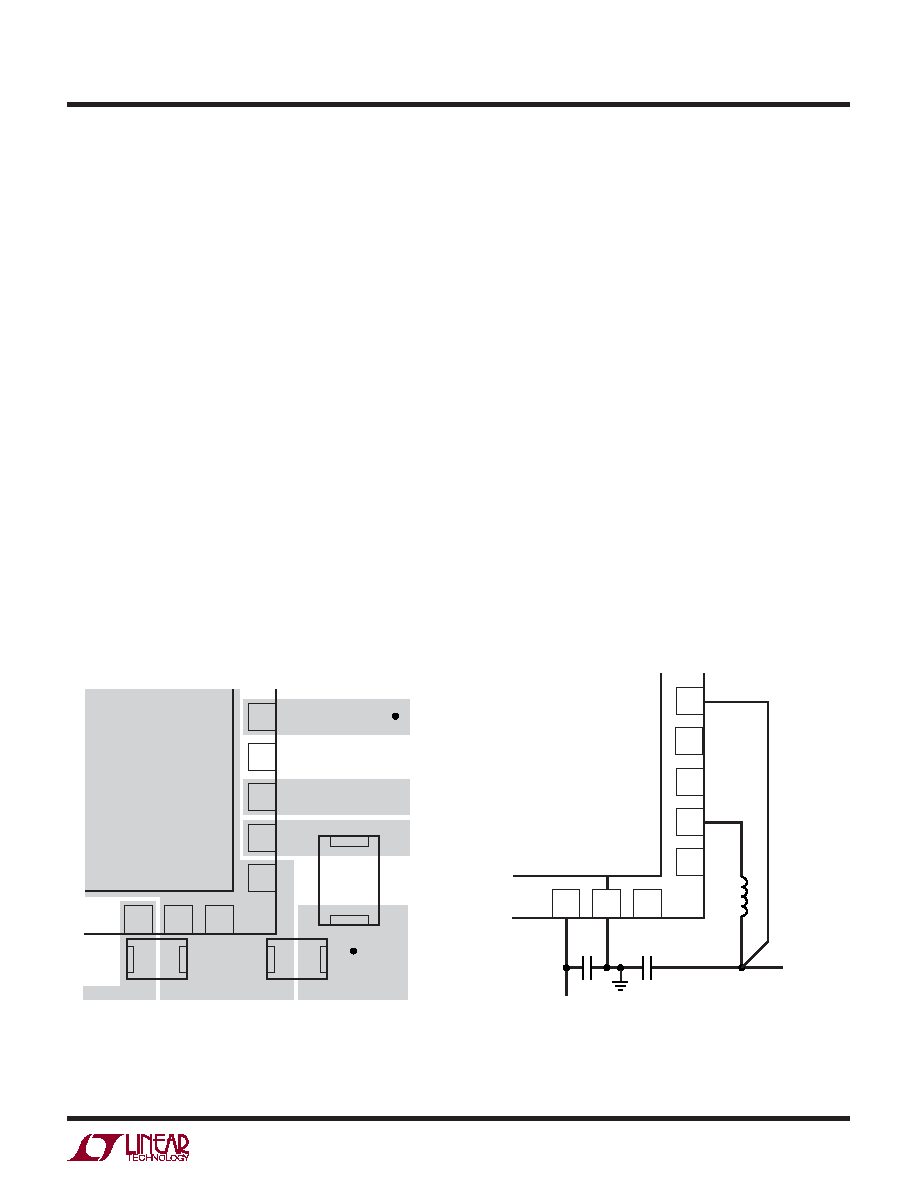

PC BOARD LAYOUT CHECKLIST

When laying out the printed circuit board, the following

checklist should be used to ensure proper operation of the

LTC3445. These items are also illustrated graphically in

Figures 9 and 10. Check the following in your layout:

1. The power traces, consisting of the GND trace, the SW

trace, the V

CC1

trace and the V

CC2

trace should be kept

short, direct and wide.

2. Does the FB pin connect directly to the output voltage

reference? Ensure that there is no load current running

from the reference voltage and the FB pin.

3. Does the (+) plate of C

IN1

connect to V

CC1

as closely as

possible? This capacitor provides the AC current to the

internal power MOSFETs.

4. Keep the switching node, SW, away from the sensitive

FB node.

5. Keep the (≠) plates of C

IN

and C

OUT

as close as possible.

APPLICATIO S I FOR ATIO

W

U

U

U

Figure 9

Figure 10

V

CC1

10

V

CC1

GND

OUT

3445 F09

SW

RUN

FB

GND

25

NC

12

GND

11

NC

13

SW

14

RUN

15

NC

16

VIA TO

OUT

VIA TO

FB

FB

17

C

IN

C

OUT

L1

V

CC1

10

3445 f10

GND

25

L1

V

OUT

BOLD LINES INDICATE HIGH CURRENT PATH

V

CC1

C

IN

NC

12

GND

11

NC

13

SW

14

RUN

15

NC

16

FB

17

C

OUT

22

LTC3445

3445fa

APPLICATIO S I FOR ATIO

W

U

U

U

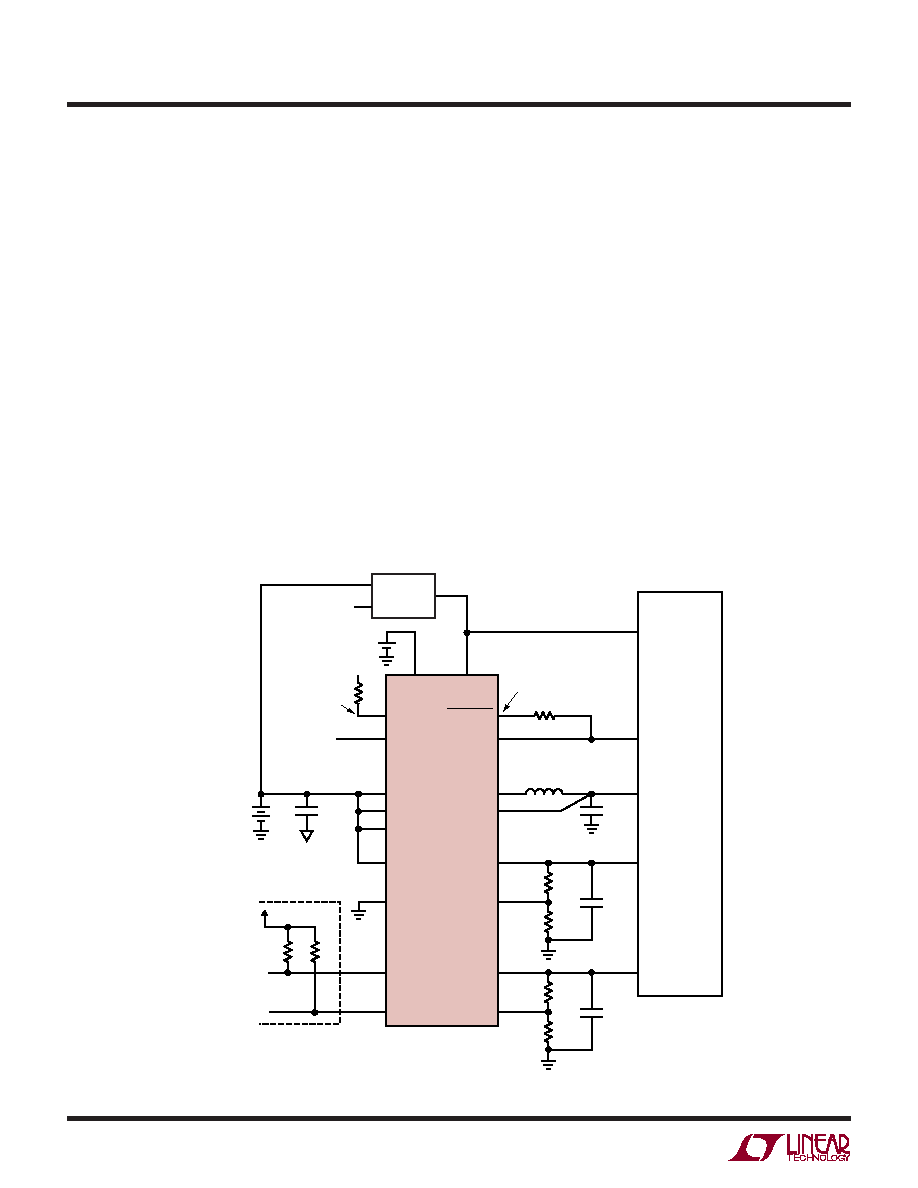

DESIGN EXAMPLE

As a design example, assume the LTC3445 is used in a

single lithium-ion battery-powered Intel PXA270 micro-

processor application. The battery will be operating from

a maximum of 4.2V down to about 2.7V. Also, the battery

will be connected to all three power pins on the LTC3445.

The desired LDO outputs are 1.3V with a 23mA load and

1.1V with a 14mA load. Since both LDO's are the same, we

will select LDO1 for the 1.3V output and LDO2 for the 1.1V

output. Using Equations 4 and 5, and choosing R2 and R4

to be 604k, the values for R1 and R2 are 705k and 503k

respectively. Also, selecting a 10

µF output capacitor pro-

vides adequate stability and transient reponses.

The PXA270's V

CC

BATT requirement can be readily handled

by the LTC3445's PowerPath control circuits. By simply

connecting a coin cell battery to V

BACKUP

, the PowerPath

control circuits regulate V

CC

BATT within the PXA270's

requirements.

The buck regulator's maximum load requirement for this

application is 300mA. Although the default start-up volt-

age for the buck regulator is 1.35V, ripple current is

greatest when the output voltage is programmed to 0.85V.

For ripple currents of 200mA and the main battery at 4.2V,

the required inductor value is 2.2

µH (Equation 1). For best

efficiency choose a 400mA or greater inductor with less

than 0.3

series resistance. Choosing a 10µF output

capacitor with an ESR of 0.25

will generate a ripple

voltage of 52mV (Equation 3). In most cases, a ceramic

capacitor's ESR will be less than 0.25

further reducing

the output ripple (see Figure 11). Note that as V

CC1

decreases or V

OUT

increases, the ripple current and ripple

voltage will decrease. The input capacitor, C

IN

, will require

an RMS current rating of at least 0.150A

I

LOAD(MAX)

/2 at

temperature (Equation 2).

Figure 11. Design Example

LDO2FB

LDO2

SDA

SCL

1.1V

3445 F11

604k

10

µF

CER

503k

V

CC

_SRAM

LDO1FB

LDO1

FB

SW

1.3V

0.85V TO

1.55V

SUMIDA

CDRH3D16/HP2R2

2.2

µH

604k

3k

3k

10

µF

CER

10

µF

CER

10

µF

CER

705k

3V_TYP

V

TRACK

V

BACKUP

V

CC

V

CC

_PLL

V

CC

_CORE

V

CC

BATT

LTC3445

LTC3406

BUCK

PWR_EN

BATTFAULT

SYS_EN

PGOOD

RUN

V

CC1

V

CC1

V

CC2

ADD7

ADD6

I

2

C BUS

3V

V

CC

_BATT

V

CC

_IO

INTEL PXA270

2.5V TO 5.5V

LITHIUM ION

3V

COIN CELL

nV

CC

_FAULT

20k

V

CC

nBATT_FAULT

20k

23

LTC3445

3445fa

U

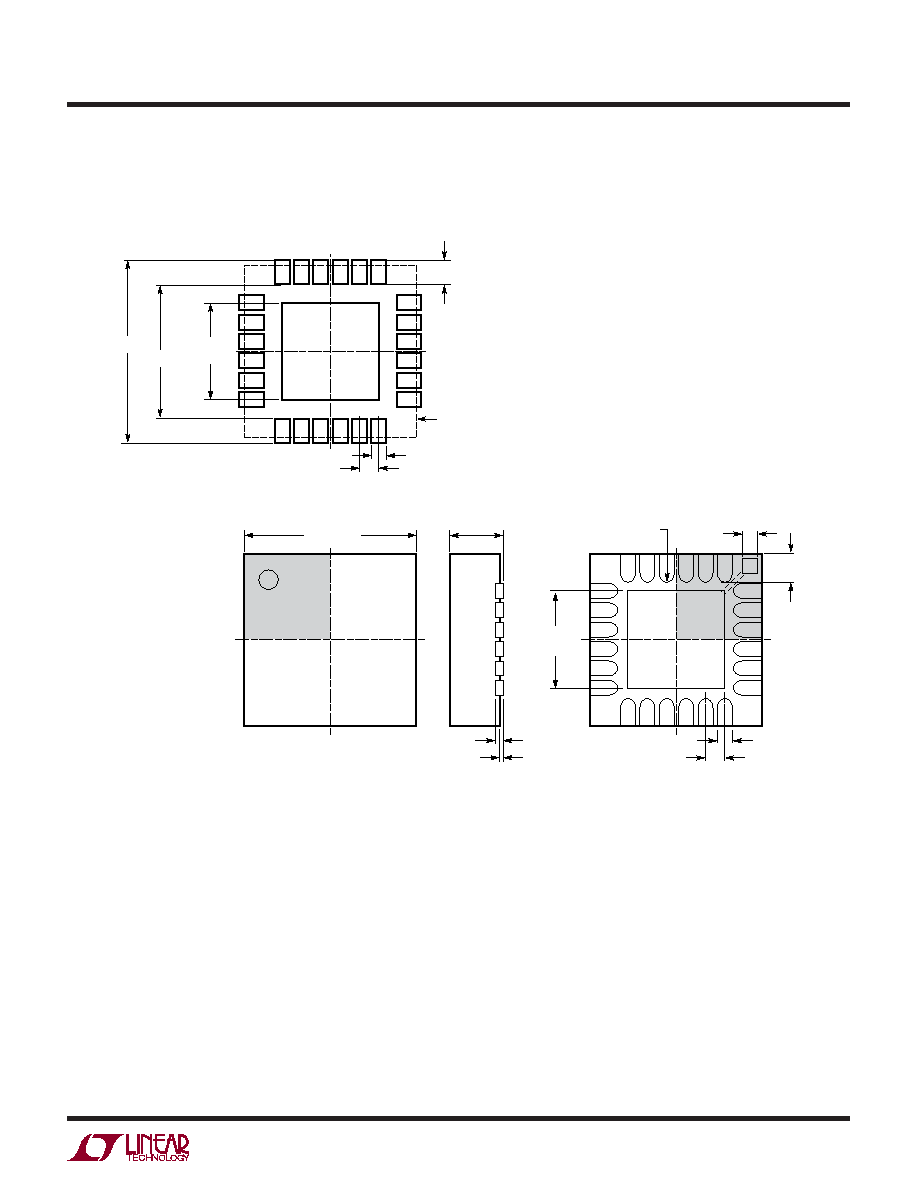

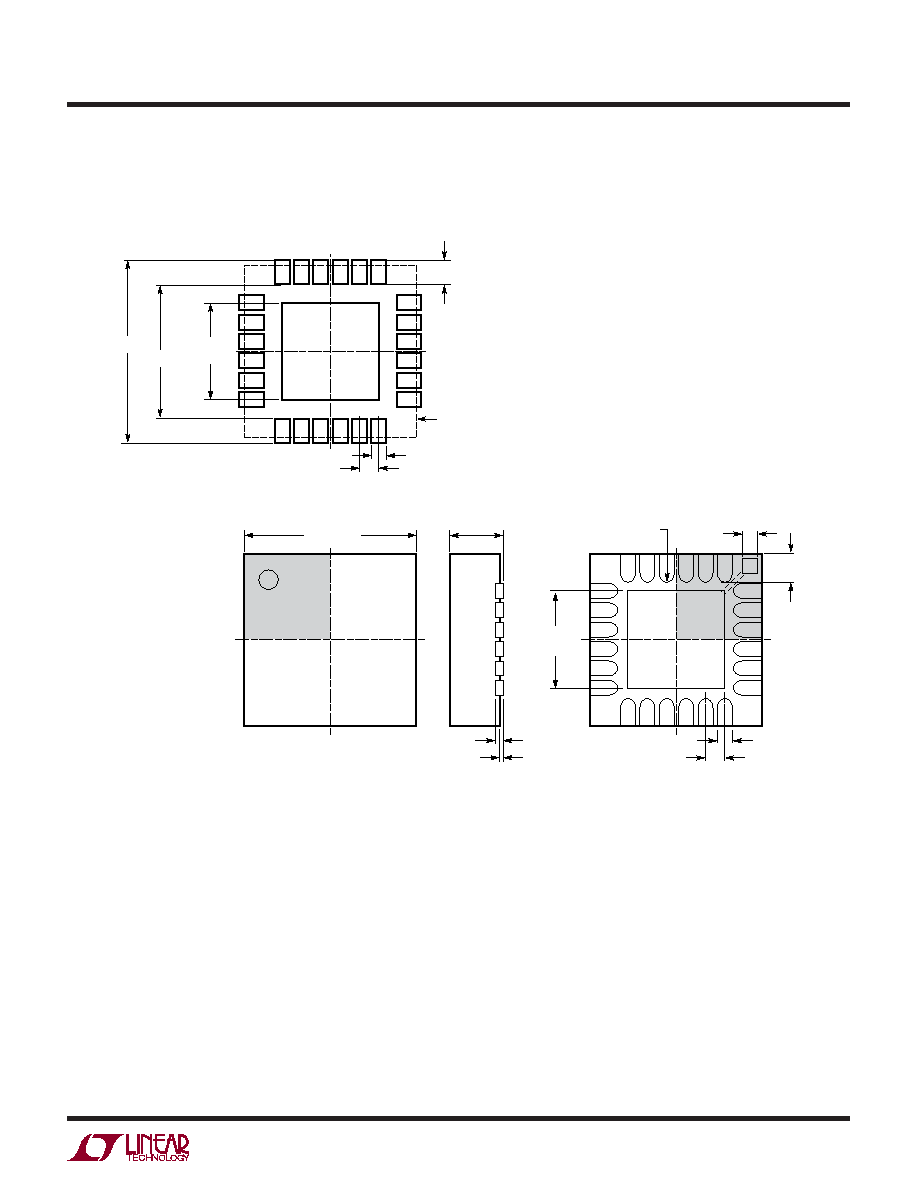

PACKAGE DESCRIPTIO

UF Package

24-Lead Plastic QFN (4mm

◊ 4mm)

(Reference LTC DWG # 05-08-1697)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

4.00

± 0.10

(4 SIDES)

NOTE:

1. DRAWING PROPOSED TO BE MADE A JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGD-X)--TO BE APPROVED

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE, IF PRESENT

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

PIN 1

TOP MARK

(NOTE 6)

0.38

± 0.10

24

0.23 TYP

(4 SIDES)

23

1

2

BOTTOM VIEW--EXPOSED PAD

2.45

± 0.10

(4-SIDES)

0.75

± 0.05

R = 0.115

TYP

0.25

± 0.05

0.50 BSC

0.200 REF

0.00 ≠ 0.05

(UF24) QFN 1103

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

0.70

±0.05

0.25

±0.05

0.50 BSC

2.45

± 0.05

(4 SIDES)

3.10

± 0.05

4.50

± 0.05

PACKAGE OUTLINE

24

LTC3445

3445fa

© LINEAR TECHNOLOGY CORPORATION 2004

LT/LT 0705 REV A ∑ PRINTED IN THE USA

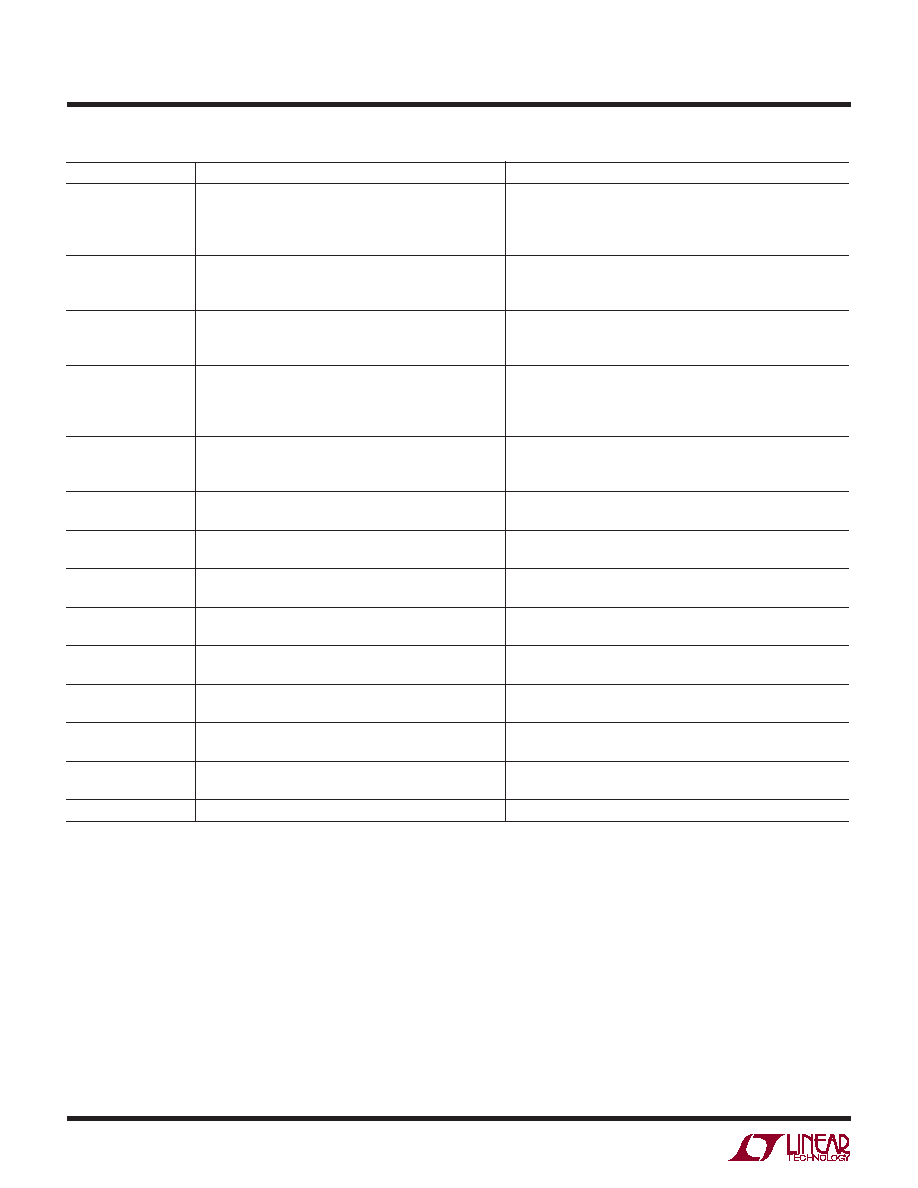

PART NUMBER

DESCRIPTION

COMMENTS

LT1761

100mA, Low Noise Micropower, LDO

V

IN

: 1.8V to 20V, V

OUT(MIN)

= 1.22V, Dropout Voltage = 0.30V,

I

Q

= 20

µA, I

SD

< 1

µA, V

OUT

= Adj, 1.5V, 1.8V, 2V, 2.5V, 2.8V, 3V,

3.3V, 5V, ThinSOT

TM

Package. Low Noise < 20

µV

RMS(P-P)

, Stable

with 1

µF Ceramic Capacitors

LT1762

150mA, Low Noise Micropower, LDO

V

IN

: 1.8V to 20V, V

OUT(MIN)

= 1.22V, Dropout Voltage = 0.30V,

I

Q

= 25

µA, I

SD

< 1

µA, V

OUT

= Adj, 2.5V, 3V, 3.3V, 5V, MS8

Package. Low Noise < 20

µV

RMS(P-P)

LT1763

500mA, Low Noise Micropower, LDO

V

IN

: 1.8V to 20V, V

OUT(MIN)

= 1.22V, Dropout Voltage = 0.30V,

I

Q

= 30

µA, I

SD

< 1

µA, V

OUT

= 1.5V, 1.8V, 2.5V, 3V, 3.3V, 5V, S8

Package. Low Noise < 20

µV

RMS(P-P)

LTC1844

150mA, Very Low Dropout LDO

V

IN

: 6.5V to 1.6V, V

OUT(MIN)

= 1.25V, Dropout Voltage = 0.08V,

I

Q

= 40

µA, I

SD

< 1

µA, V

OUT

= Adj, 1.5V, 1.8V, 2.5V, 2.8V, 3.3V,

ThinSOT Package. Low Noise < 30

µV

RMS(P-P)

, Stable with 1

µF

Ceramic Capacitors

LT1962

300mA, Low Noise Micropower, LDO

V

IN